To ensure environmental sanitation, the Socialist Republic of Vietnam have required factories, industrial zones, Free-trade zone, etc. must equip with standard wastewater treatment systems. To remove harmful chemicals in wastewater and sludge before being released into the environment. One of the most effective assistants that investors trust is sludge press(es).

So what is the role of the sludge press in the wastewater treatment system and why is it necessary? Let's find out with ARK Vietnam in this article.

1. SAVE WASTEWATER TREATMENT COSTS

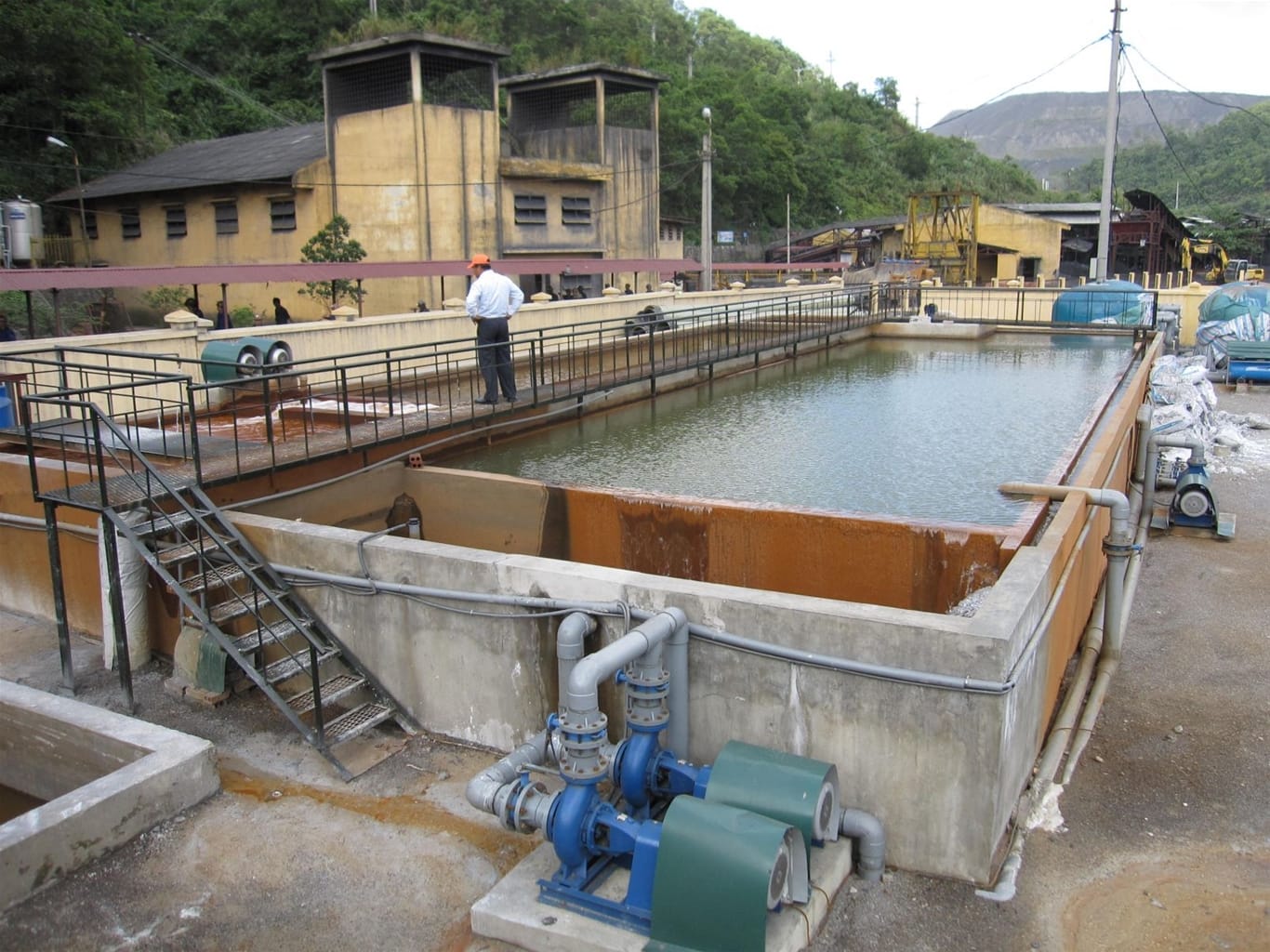

Previously, manufacturing enterprises had to spend a huge cost to treat sludge annually. The cost is mainly coming from hiring workers and renting sludge trucks from third parties. You well knew that the settling tanks in the wastewater treatment system will be filled with sludge after a while. Sludge settles and sticks firmly to the tank wall under the pressure of gravity. It is compulsory to hire workers and vehicles to scoop up the mud. However, it is very expensive and not hygienic.

This is just a temporary solution, the problem is not completely solved

Especially in the chemical manufacturing industries - cosmetics, food, printing ink, the sludge from the wastewater treatment system will have a stench and be extremely toxic. Extremely harmful to the environment and workers' health. Therefore, investors always have a headache about a better sludge treatment solution.

Since then, the sludge presses were researched and invented, meeting the huge demand for wastewater and sludge treatment. Not only better but this is also considered the best solution available today. The slurry press is increasingly showing its necessity. Become an indispensable piece in professional sludge treatment systems.

The most important is the purchase of a sludge dewatering machine will help companies and factories to save the cost of hiring a transport unit to dump the sludge. Because after being filtered, pressed, the volume and weight of the sludge will decrease significantly. The sludge is neatly packed, odors are minimized. Transport quickly and safely to the sludge treatment site, saving the number of trips.

2. SAVE TIME ON SLUDGE TREATMENT IN WASTEWATER TREATMENT

Among the wastewater and sludge treatment solutions, the application of a sludge press is the most economical investment, economically beneficial, and time-saving.

Previously, sludge treatment took workers had to work many days or a month to dredge, dry mud in the yard (traditional ways). Currently, the most modern, high-quality mud presses can work 24/7, with high efficiency and freeing human labor.

3. SAVE POLYMER, WASTEWATER TREATMENT CHEMICALS, AND SET-UP AREA

To treat wastewater effectively, polymers (or coagulant chemicals) must be used. This chemical is especially necessary with certain types of wastewater. If the customer is using a plate-frame slurry press (filter-press) (which uses old technology), the polymer will not be needed. But the machine cannot work continuously. But collecting the mud cake from this machine is very hard.

If using new generations of slurry presses (such as screw presses, decanter centrifuges), polymers are essential.

However, compared to the traditional sludge treatment method, it is more economical to use coagulant chemicals for the sludge press. The dryness of the pressed sludge is stable, the sludge dewatering machine works optimally all day long. In short, the investment cost will be significantly cheaper.

See more: Why investment in sludge dewatering purchasing is right and profitable?

WHAT IS THE PRESTIGIOUS MANUFACTURER OF SLUDGE PRESS IN VIETNAM?

ARK Vietnam is proud to be a manufacturer with more than a decade of experience in the field of Consulting - Manufacturing - Setting up sludge press machines in Vietnam. Inheriting 30 years of operation in the industry, with modern production lines from ARK Korea. Our company currently focuses on producing the three most modern mud presses. Our products were trusted by domestic and foreign investors:

In addition, ARK Vietnam also provides auxiliary equipment for sludge presses such as:

- Coagulation polymer;

- Metering pump;

- Polymer dissolution tank;

- Replacement components. Repair and maintenance support service all kinds of sludge presses according to Korean standards and ISO 9001:2015.

ARK Vietnam is a manufacturer possessing core technology, fully equipped with modern production lines. We have a team of skilled engineers and workers with many years of experience, who are willing to survey reality, collect information, and consult efficient wastewater and sludge treatment equipment, suitable to the financial conditions and production scale of customers.

When choosing ARK Vietnam, you will never be disappointed

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.