Confectionery wastewater treatment is a difficult problem posed in the context of the confectionery industry in our country has grown strongly in recent years.

Not only serving a huge population that has reached 100 million people, but the confectionery industry in Vietnam also has great export prospects with promising consumption markets in China, Southeast Asia, Europe, and North America. Accompanying all production industries, there are always issues related to the environment, especially in confectionery wastewater treatment.

Experts commented that: "If an appropriate, immediate and effective solution is not found, environmental problems will accumulate, leading to an unfortunate consequence". Therefore, as a business investor, or an environmental engineer, do you have an overview of the ingredients, as well as the process of treating confectionery wastewater? Let's find out with ARK Vietnam below.

Confectionery production – unicorn start-up of the new decade

Confectionery must have been familiar to us since our childhood days. The confectionery industry also follows the momentum of integration and develops continuously.

This is considered one of the essential manufacturing industries today. Indeed, because the demand for this item is immense. You see candies in every holiday, Tet, festival, party, religious activity, and daily life.

Confectionery is also a traditional craft with specialties for each region and each locality. Each place has its advantages and strengths in terms of confectionery, in parallel with confectionery on modern Western chains. Our country advocates not only for domestic development but also for this industry to be encouraged to export to the world market.

The large source of income entails a large amount of investment, solving an important part of jobs for a large class of Vietnamese workers. However, every coin has 2 sides, along with super benefits, we are facing serious environmental pollution caused by confectionery wastewater.

Confectionery wastewater, where does it come from?

There are two basic sources of wastewater – which I have to use two words: “complex” and “stubborn” in treatment:

- The first source is in production: All confectionery production processes from traditional to modern have to go through the stages of preliminary processing, cooking of ingredients, packaging, and cleaning of machines. Since then, wastewater begins to generate huge volumes.

- In daily life: Wastewater comes from the activities of employees in the toilets, dining areas, dormitories, etc. In the cooling and cooling stages of the industrial machinery system. A confectionery factory has a large number of workers and machines. They are also concentrated in complexes with the joint venture investment of foreign confectionery groups.

Ingredients in confectionery wastewater

Why, at the beginning of the article, has emphasized the danger and urgency of this type of wastewater. Before going to learn about the technological process of confectionery wastewater treatment, let's find out why its composition and properties are so complicated.

Different from other common wastewater, confectionery wastewater has different compositions depending on each input material. There are millions of different candies with billions of ingredients.

However, they still have in common that they contain a very high concentration of organic pollutants. Suspended solids (SS), fats, oils, and greases lead to a large chemical oxygen demand (COD) which makes the treatment process very time-consuming and costly.

|

Parameter |

Unit |

First value |

QCVN 40:2011/BTNMT |

|

|

Column A |

Column B |

|||

|

pH |

– |

5,5 – 10,5 |

6 – 9 |

5,5 – 9 |

|

BOD5 |

mg/l |

1200 |

30 |

50 |

|

COD |

mg/l |

1850 |

75 |

150 |

|

TSS |

mg/l |

500 |

50 |

100 |

|

Total Nito |

mg/l |

42 |

20 |

40 |

|

Total Phosphorus |

mg/l |

9,5 |

4 |

6 |

|

Grease |

mg/l |

150 |

5 |

10 |

|

Total Coliforms |

MPN/100ml |

10^4 – 10^5 |

3000 |

5000 |

Detailed composition table of confectionery production wastewater

Confectionery wastewater treatment technology

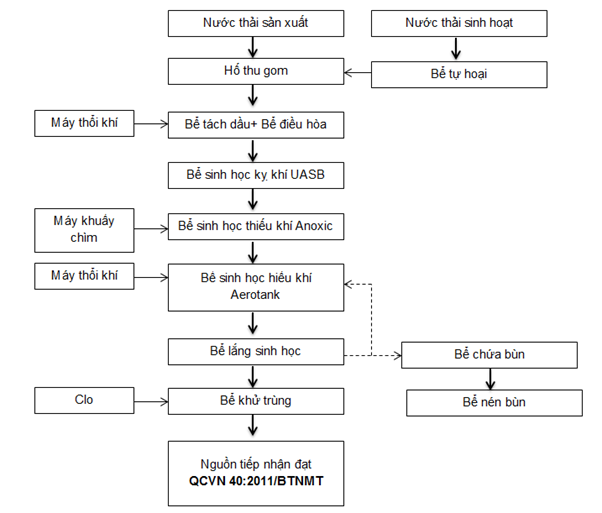

Để có một quy trình xử lý nước thải bánh kẹo thật hiệu quả, thật tiết kiệm, nhiều doanh nghiệp sản xuất bánh kẹo hiện nay đang áp dụng dây chuyền xử lý với sơ đồ, cũng như nguyên lý hoạt động của các loại máy móc như sau:

Principle of operation

According to the mentioned two sources, confectionery wastewater in the production line will be collected directly from the collection tanks. While domestic wastewater will go through the necrosis tank and then be taken to the collection tank.

After that, the confectionery wastewater will be pumped in turn to the tanks to serve the treatment process. A series of processes will include an oil separation tank, conditioning tank, AAO microbiological technology, settling tank, and sterilization tank.

1. Oil separator tank

Wastewater after collection will be pumped directly into the oil tank, to remove the grease floating on the water surface. Grease is insoluble in water, so it can be easily removed to avoid damage to machinery.

If oil separation is neglected or performed inefficiently, pump clogging and inhibition of biochemical microbial activity are certain.

2. Air conditioning tank

Regulating the concentration of pollution and balancing the confectionery wastewater flow is the task that the conditioning tank undertakes. At the tank, air will be supplied from the air blower system to continuously stir, prevent the growth and decomposition of microorganisms that cause stench, and at the same time generate many unpredictable toxic substances.

3. Microbiological Technology AAO

Wastewater passing through these two tanks is also the end of the preliminary process in confectionery wastewater treatment. This is only a mechanical treatment process, so the content of organic pollutants in wastewater is still very high. At this time, biochemical technology with the microbiological agent AAO will be used to remove them.

This technology is a combination of three tanks: anaerobic, anaerobic, and aerobic. Through that, organic pollutants will be decomposed and converted into CO2, H2O, beneficial microorganisms, etc. At the same time, the stench in the confectionery wastewater will no longer exist.

The chains of biochemical and oxidative reactions take place extremely complex leading to increased biomass of specific microorganisms.

The key to this stage is to select microorganisms that are capable of good treatment of pollutants present in wastewater

Biological methods of wastewater treatment based on microbial activity. Therefore, for the wastewater treatment process to achieve optimal efficiency, shorten the operating time, culture, and microbiological quality are the core factors that wastewater treatment system operators need to understand. . Microorganisms need to meet the following conditions:

- Quick activation (liquid will activate better).

- 100% working rate.

- Strong activity, can decompose difficult to decompose organic substances.

- Good adaptability to many environments.

- Easy to use, store, and culture.

4. Sedimentation tank

In the next stage, wastewater will continue to be brought to the settling tank to remove the microbial biomass just created above. Thanks to gravity, the flocs will gradually settle to the bottom of the tank. The above water will automatically be decanted to be taken to the sterilization tank.

Part of the sludge will be returned to the Aerotank tank to maintain the concentration of microorganisms in the tank, helping the biochemical reaction chain to be maintained continuously. The remainder will be taken to the sludge tank and periodically removed.

5. Sterilization tank

The amount of confectionery wastewater is now relatively up to some standards, the disinfection tank is near the end. People pump here a suitable rate of chlorine to destroy coliform, dangerous bacteria that cannot be destroyed in the above tanks. Excess chlorine must be removed because chlorine is, after all, a common carcinogen.

After that, wastewater will be discharged into the environment according to the discharge standards prescribed by the State.

Confectionery production wastewater after treatment is mainly used for the following purposes:

- Agricultural irrigation.

- Watering plants, washing floors, washing roads, washing cars.

- Reusable in several industries.

- Give water to the reservoir to create a landscape.

- Use for circulation or other purposes.

The sludge in the sludge storage tank is pumped into the sludge dewatering machines, removing the water, and reducing the volume of the sludge. Dry sludge is collected and treated periodically. In the sludge tank, the air is supplied to reduce the odor generated.

The water after passing through the pressure filter tank meets the discharge standards to the receiving source by the regulations QCVN 40:2011/BTNMT column A.

Advantages and disadvantages of confectionery wastewater treatment process

No matter how advanced a wastewater treatment process is, it cannot avoid certain limitations. Please list a few of the most obvious features

Advantages

- High efficiency in the treatment of organic pollutants in wastewater. Reduce BOD, COD, Nitro... effectively.

- This system is highly appreciated and becomes an optimal system today both in terms of technology and cost.

- The scale of the confectionery wastewater treatment plant is not too large, and the above process is stable and not too complicated.

- Construction, operation, and maintenance costs are not too large, and relatively suitable in the context of an economic downturn.

- The concentration of pollutants meets the standards according to the current output standards of the State.

Disadvantages

- Impurities such as sludge, grease, or solids are removed, and there will be a complex separate treatment process and new investment.

Therefore, when your business invests in the field of confectionery production, do not ignore the reference and assessment of the advantages and disadvantages of the processing process. And let's not forget ARK Vietnam, we are proud to be a professional and reputable unit in the production, consulting, and installation support of high-quality mud presses.