Sludge storage tank, sludge compaction tank is one of the basic and mandatory components in any wastewater treatment system today. This place can be said to be the final stage of the processing process as we know it. Whether the sludge meets the criteria for discharge into the environment or not, may have been decided at this stage.

The actual situation of industrial-scale wastewater and sludge treatment

Most of the cycles from the rudimentary to the most advanced go through the process of collecting wastewater and leading to storage tanks for initial sedimentation. Right from this step we were able to separate a large part of the water from the sludge.

At many water treatment plants, most of the sludge water generated daily is collected and led to reservoirs or sedimentation ponds and then discharged directly into ponds, lakes, and rivers. Stages 2 and 3 have received little attention to save costs.

However, the lack of sludge compaction area will cause a lot of loss of clean water that can be reused, untreated sludge will be a source of pollution for surface water and groundwater. “As urgent as the need for clean water supply is, the problem of sludge treatment, waste sludge utilization, and sludge separation arising in treatment at the plant also needs to be improved. This also aims to minimize the impact on the surrounding habitat".

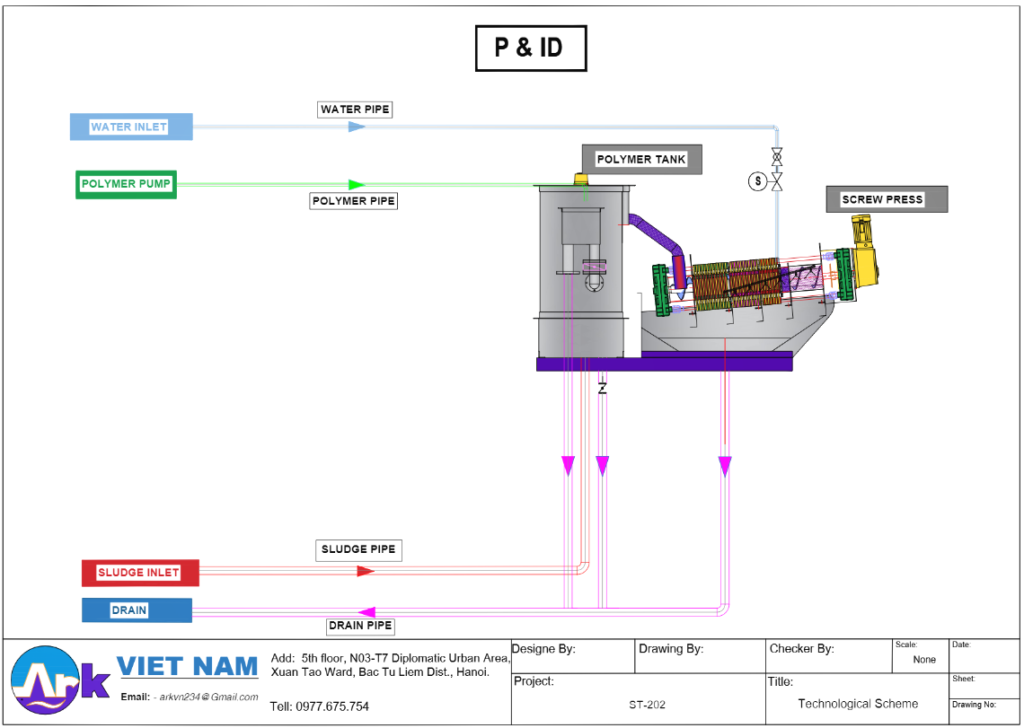

An effective comprehensive sludge collection and treatment solution must build a combined sludge water treatment system including a system of ditches to separate the flow of sludge and water to the sludge tank and the sedimentation tank, to recover water. washing filter, sludge compression tank, sludge press, sludge pumping system, water, chemical pump... The initial cost for the system investment is about 1 - 2 billion VND depending on the size and amount of waste to be treated.

What is a sludge tank?

The sludge storage tank is a biological tank that specializes in acting as a storage area for the sludge generated before, during, and after the wastewater treatment process. From the storage tank, the sludge will move to areas with the function of collecting, further processing, and discharging sludge.

Sometimes, the sludge tank is also equipped with an aerator to prevent the growth of anaerobic microorganisms, resulting in the production of harmful toxins. Especially in chemical factories, fabric dyeing, confectionery, ... where the biochemical composition of wastewater is extremely complex.

In addition to the main role of collecting and reducing sludge, the sludge tank also supports faster sludge treatment, promoting the treatment efficiency of the entire wastewater system. With a large tank capacity and closed tank, the system avoids clogging or leakage of waste.

How to calculate a sludge tank?

When calculating the construction of a sludge tank, the volume of the tank will depend on the location of the tank in the system. For example, when you want to have a sludge tank located behind the settling tank, its size will be smaller than that of the settling tank because its bottoms are connected.

The volume of the sludge storage tank in the wastewater storage area will depend on the treatment capacity and the flow of water pumped into the tank.

In addition, the most important is still the investment cost that the business can spend. As the size of the sludge tank increases, the cost will increase, so calculate the discharge capacity as well as the treatment capacity. Your machines must be equally capable, so consider the new generation of advanced slurry presses, branded ARK Vietnam.

What is a sludge compactor tank?

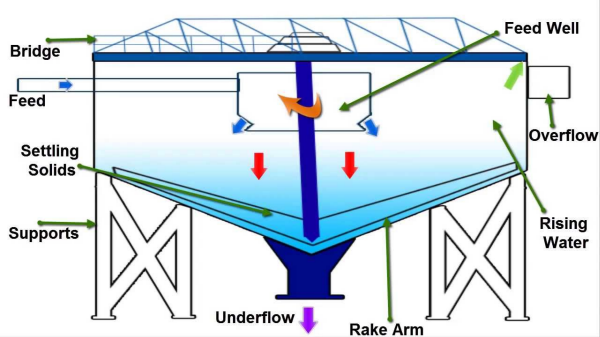

Next is the sludge compaction tank. Sludge compaction tanks in industrial wastewater treatment systems and domestic wastewater systems operate by gravity in a circular settling tank.

Anyone can imagine the function and image right from the name.

The dilute solution wastewater will go to the center of the tank, the sediment after settling will be removed from the tank and the water will go another way back to the treatment system. Simply put, this is a natural mud press that does not require electricity.

The dilute solution wastewater will go to the center of the tank, the sediment after settling will be removed from the tank and the water will go another way back to the treatment system. Simply put, this is a natural mud press that does not require electricity.

Working Principle

The sludge compaction tank works on the same principle as the circular settling tank. The wastewater solution will enter the pipe area in the center of the tank. With the action of gravity in a static environment, with little vibration and stirring, the sludge in the water will automatically settle to the bottom due to molecular affinity.

The clean water with a lower specific gravity will be on the surface side and easily sucked out thanks to the trough around the tank.

Some large-capacity systems also have a descaler at the bottom of the center of the slurry tank. When the sludge settles down, the mud wiper will wipe them to compress them to the bottom of the tank faster. At the bottom of the tank will be attached to the sludge press, to maximize the amount of water extracted. Thereby reducing the volume of dry sludge.

With the above system, so that the water can move convectively upwards on the face, the lever area of the wiper is mounted from wooden or steel rods. As the machine moves around the shaft, these rods will stir the scum mass so that the water rises, making the slurry thicker.

Common types of sludge compression tanks

There are quite a few types of sludge compactors with different characteristics in terms of construction materials and core principles.

Depending on the nature of the waste as well as the budget, each system will choose an appropriate type of tank. Basically, a sludge compression tank includes 2 types below:

- Gravity sludge tank: this type of tank relies on pressure to operate. The tank has a piston that takes on the role of removing the water in the slurry, completing the basic compression and pressing.

- Aerobic sludge digestion tank: application of the aerobic microbiological method to promote sludge decomposition through intracellular decomposition of bacterial cells. It relies on the oxygen-consuming respiration of bacteria in the sludge. As a result, beneficial microorganisms will decompose residues and wastes in the sludge to increase sludge production, or reduce sludge volume, returning more clear water.

Calculation of sludge compaction tank in the treatment process

If the calculation and design of the above sludge tank are quite simple when you only need to care about the volume, with the sludge compaction tank, the planner needs to pay attention to more factors.

- In terms of height, the internal sludge compaction tank is usually from 3 to 3.7 m high. Which, the central pipe also occupies from 1 to 1.25 m and the diameter is about 10 to 20% of the diameter of the whole tank.

- The area of the compression tank is calculated based on the sludge load. Therefore, the area will be decided based on the survey of each type of sludge. The volume of the sludge compaction tank is calculated according to the storage time so that the amount of sludge can be increased or decreased accordingly, to ensure that the system is not stagnant.

The retention time inside the tank is calculated as the volume of the sludge reservoir divided by the amount of sludge removed per hour.

- Specifically, based on the surface load of the tank, the surface load is in the range of 24 - 30 m3/m2/day.

- Surface load = Q (m3/day) / S (area of the tank m2)

- The volume of the sludge compaction tank is tested according to the retention time in the tank from 0.5 to 20 days, which is inversely proportional to the outdoor temperature, in hot and humid weather, the smallest value is taken.

- Retention time inside the tank is equal to the volume of the sludge storage area (usually from 1.7m to 2.4m in height) divided by the amount of sludge removed from the sludge compaction tanks by an hour of the day.

Summary

Above is the basic information about sludge storage tanks, and sludge compression tanks. With the role of each type of tank as well as the calculation method, we can see its importance. Although it has the simplest design in the system.

Therefore, your business should not ignore the construction of these types of tanks to ensure the results of the whole process. And let's not forget ARK Vietnam , we are proud to be a professional and reputable unit in the production, consulting, and installation support of high-quality mud presses.