Sludge dewatering wastewater treatment is a sludge dewatering device that produces sludge in a solid state for easy transportation, destruction, and pollution-free water and then discharged into the environment. The equipment helps to increase the sludge treatment capacity many times compared to the old technologies, such as drying and natural settling.

In industrialized countries, they used sludge dewatering machines in the final stage of wastewater treatment, decades ago. Up to now, developing countries have also applied this sludge pressing technology to their sludge treatment.

Overview of the Sludge dewatering

| English name | Máy tách nước bùn |

| Solids recovery rate | 80 – 95% |

| Durability | High (long-term use) |

| Producer | ARK Vietnam |

| Processing Time | Fast (minutes or hours) |

| Materials | Stainless Steel |

| Chemical consumption | polymer create mud cotton |

| Dimension | Compact (doesn't take up space) |

The device is widely used in waste management, which saves money by reducing costs, and the time for solids disposal or disposal is calculated on a unit weight basis.

Why is Sludge dewatering necessary in wastewater treatment

The device is widely used in waste management, which saves money by reducing costs, and the time for solids disposal or disposal is calculated on a unit weight basis.

With large-scale production plants and densely populated cities, the amount of sludge generated is increasing. Become a challenge with the processing lines, the burden on investors.

The sludge dewatering was born to solve the above problem. In fact, they are capable of producing slurry with a dryness that is superior to that of basic filters. The effective separation of sludge juice is to increase the solids concentration. Reduce the volumetric mass of the mud cake for easy, cost-effective handling.

The effective dewatering increase the solids concentration. Reduce the volumetric mass of the mud cake for easy and cost-effective handling. Sludge disposal is followed to strict regulations. Residential areas, industrial zones, cities and provinces all have certain goals for sustainable development. This includes environmental requirements.

Current new sludge pressing technology

In addition to the old sludge pressing technologies such as drying, natural settling, vacuum filter. We have new sludge pressing technologies such as centrifugal, screw, belt, filter press.

Currently, most advanced countries using new sludge pressing technology is to use decanter centrifuge as the main equipment in wastewater treatment. However, depending on the specifications and investment costs of each method, you can make a technology choice that is reasonable for your business.

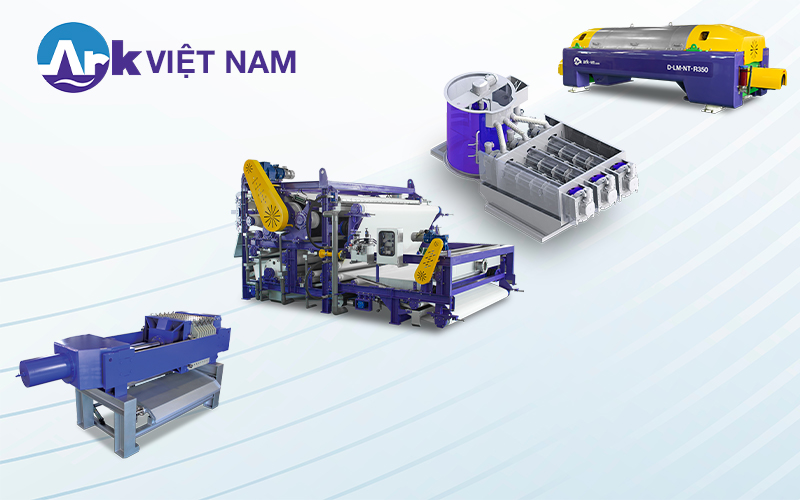

4 Popular dewatering equipment 2022

The sludge dewatering machine is gradually replacing the old dehydration methods in developing countries because of its convenience and extremely strict requirements by the government. Here are 4 types of mud presses on the market:

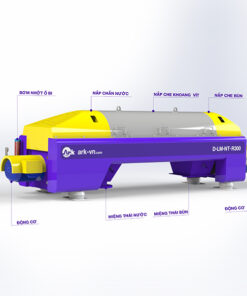

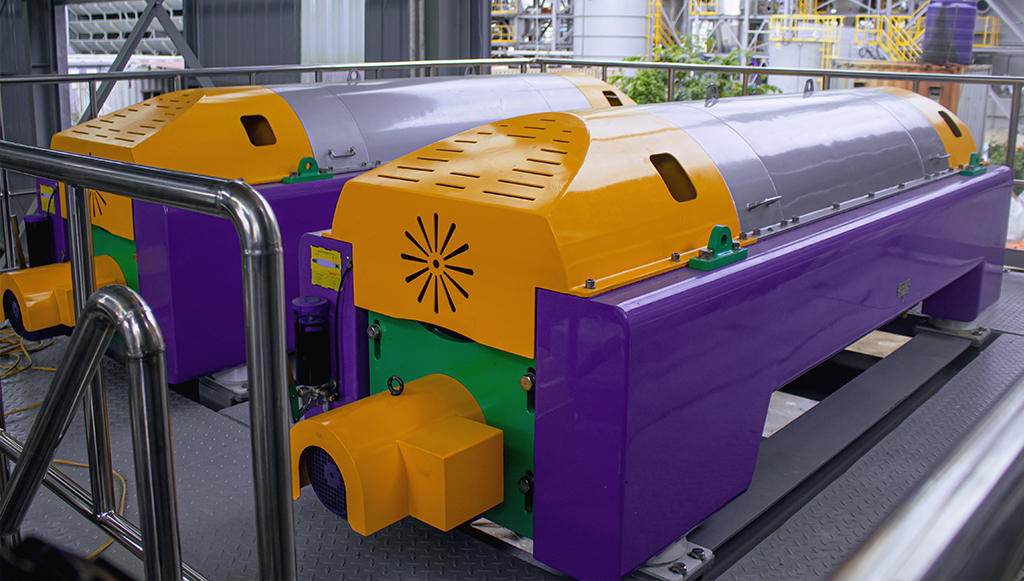

1. Decanter centrifuge

Centrifuge is applied with modern technology, best materials, with equipment Closed design anti-odor, affordable price. Products deserve to be trusted and chosen by businesses.

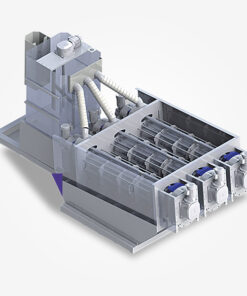

2. Screw press

Screw press can be used instead of machine conveyors, centrifuges or plate frame machines. It is a simple, slow-moving, power-efficient device that completes dewatering by continuous gravity draining.

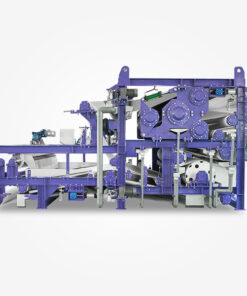

3. Belt press

belt-press commonly used in chemical industry, mining. The machine is loved by businesses because of its extremely easy operation.

4. Filter press

filter press was introduced in the first generation of dehydrators. It is cheaper and costs very little polymer. However, when using this product for a certain period of time, there will be problems with the need to change the filter.

Benefits of using sludge dewatering machine

Waste volume reduction

Because sludge dewatering focuses on weight and volume reduction to minimize waste disposal costs, as the name of the method implies, water removal is the principal means to reduce volume before the sludge by-product can be economically disposed of.

Reduced transportation costs

Managing sludge can be a costly business. Dry, high solids cakes mean lower costs. Use of dewatering equipment is an effective tool for managing sludge accumulation, reducing both transportation costs and storage expenses.

Consistent cake dryness with lower risk of spilling/leaking

The dry, high solids cakes not only mean lower costs of transport but also provide a lower risk of spilling/leaking onto the roads. This is a major issue, particularly when trucking through residential areas.

Wastewater recycling

Recycling wastewater is another benefit of sludge dewatering. Once the treated water from sludge dewatering is free of hazards and contaminants, it can be reclaimed by industries and communities. Though the water is typically non-potable, it still has many applications.

Equipment is easily automated

A lot of folks think of sludge dewatering as labor-intensive pieces of equipment. But, in fact, sludge dewatering can come with automatic cloth washers, mechanically-assisted cake release, and sophisticated control systems, allowing communication to the main plant control system, all making sludge dewatering much easier. Such as máy

ép bùn công nghệ cao made by ARK Vietnam.

Eco-friendly

Finally, sludge dewatering is environmentally friendly, reduce pollution. In addition, it saves water and recycles precious resources.

Frequently asked questions

What is the sludge dewater machine for?

sludge dewatering to waste minimization and to achieve overall cost efficiency for disposal. Additionally, stabilized sludge can be handled more safely and can reduce health hazards. Some sludges actually have a great beneficial reuse and can be land applied.

Why is sludge dewatering necessary?

Because sludge dewatering helps cut down on disposal costs by reducing the volume of water-saturated soil. It can also help save between 75 to 80% of transportation and storage expenses.

What is dewatering in Wastewater?

In the simplest terms, dewatering is the removal of liquids from a sludge slurry. The process involves using one of three dewatering techniques. The three techniques are screw press, centrifuge and belt press.

What is the difference between sludge thickening and dewatering?

Sludge thickening normally refers to the process of reducing the free water content of sludges; whereas, dewatering refers to the reduction of floc-bound and capillary water content of sludges.

When mentioned about wastewater treatment, ARK's sludge dewatering is the perfect solution to save costs. Proven to reduce waste. The machine is effective on most sludge, suitable for all industries.

ARK Vietnam is a reliable choice for effective sludge pressing solutions. We provide the complete solution including system design, installation of sludge dewatering, polymers supply, auxiliary equipment, to meet your needs.

[khối id=”footer-post”]