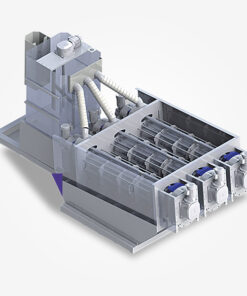

Screw press (Multi-disk type) is being used most by businesses in the treatment of sludge. The device has high applicability in many factories, industrial parks and different industries, especially the ability to save costs on building wastewater treatment systems, which are already very complicated and expensive.

We have decades of innovative research and developmental achievements of screw press in South Korea. ARK has brought to Vietnam the optimal solution for your business's sludge and wastewater treatment since 2011. We have experience implementing many projects, which used many advanced and modern multi-disk screw presses, satisfied the demand of small and medium-sized enterprises to multinational corporations. ARK's machines play a pivotal role in sludge and wastewater treatment projects.

Multi Disk Screw Press

Screw press của chúng tôi hoạt động liên tục trong nhiều dự án, bền bỉ trong các môi trường khác nhau. Phù hợp với nhiều loại nước thải có tính chất hóa lý phức tạp. Không chỉ phục vụ thị trường Việt Nam, ARK còn được nhiều đối tác nước ngoài “Try before you trust”.

| Technology | the Republic of Korea |

| Number of screws | 1 – 4 |

| Materials | STS304, SUS316 |

| Maximum capacity | 150 kgDS/giờ |

| Sludge concentration | 0,6% – 3% |

| Features | convenient for cleaning, maintaining |

| Outstanding highlights | Compact, energy-saving |

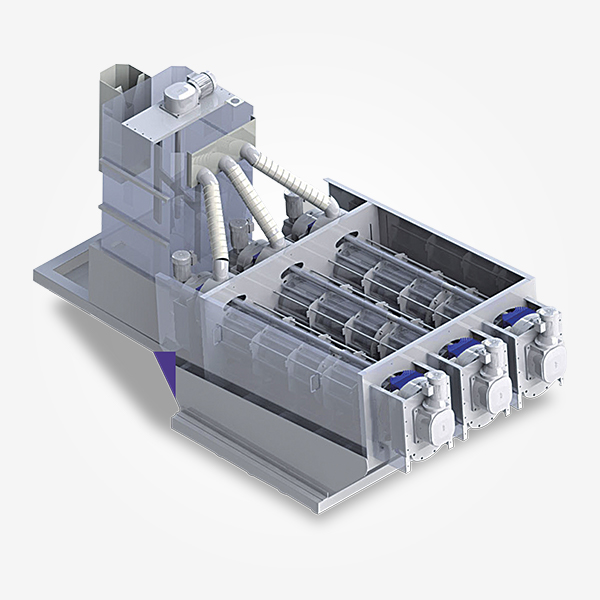

The screw-press is used in the final stage of the processing process and has been improved in many ways. Compact size requires a smaller installation space. The screw system is designed to resist wear. The sludge-polymer reaction tank has a smart structure and is more efficient than the older generation screw-presses.

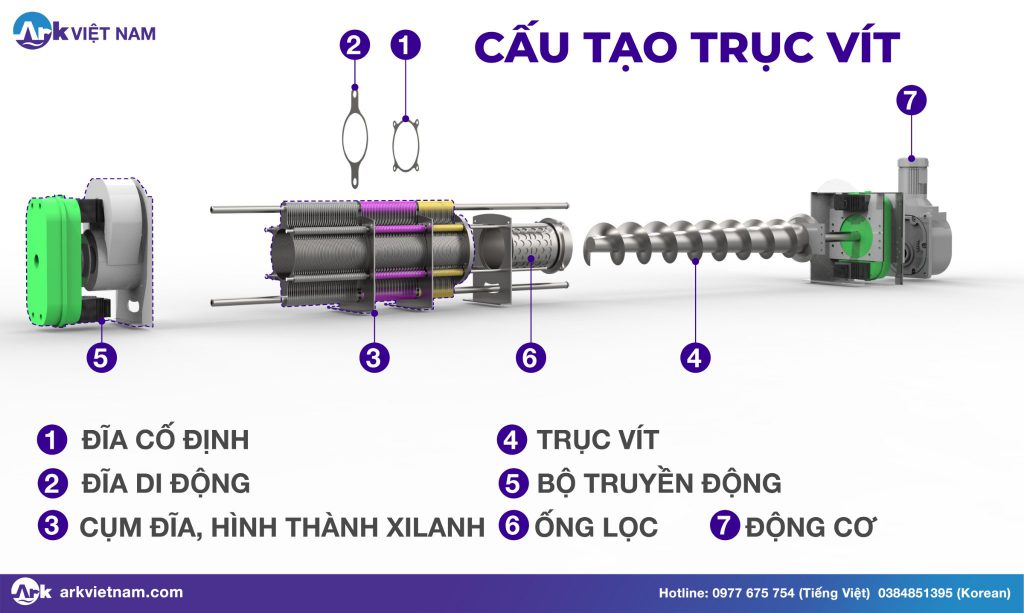

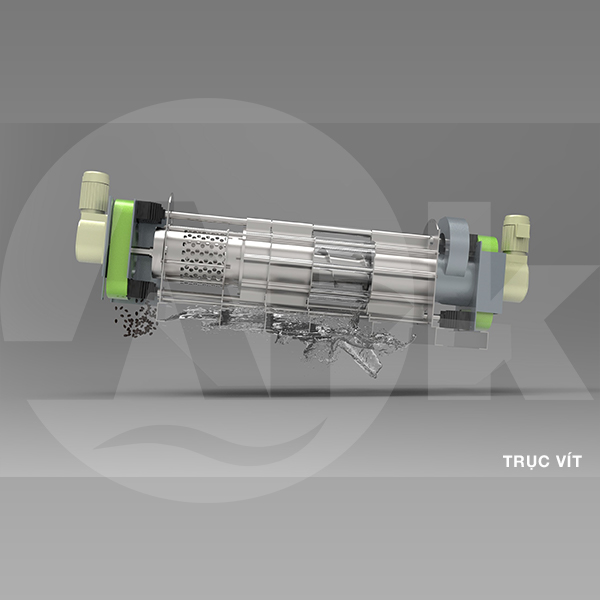

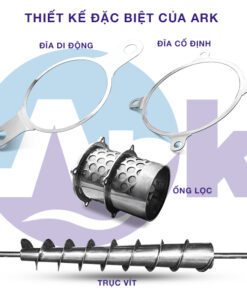

Structure screw press

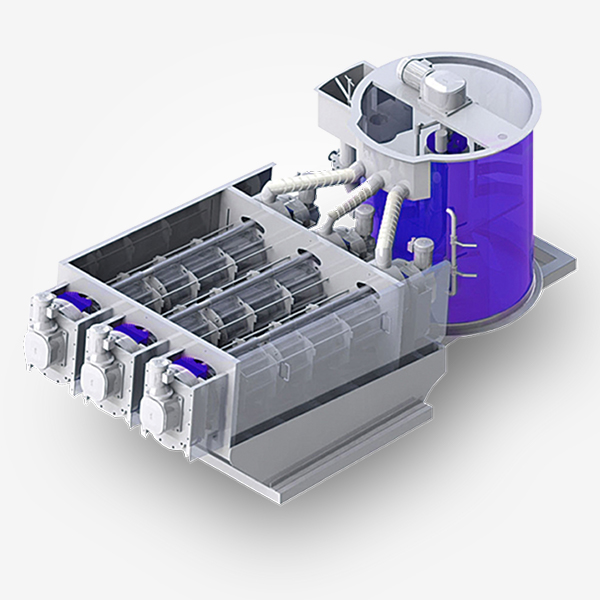

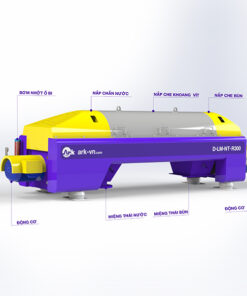

The screw press made by ARK Vietnam includes a sludge-polymer reaction tank, which feeds the sludge to the body (screw). We provided two main types of products: RT and ST. They differ in the structure of the reaction tank.

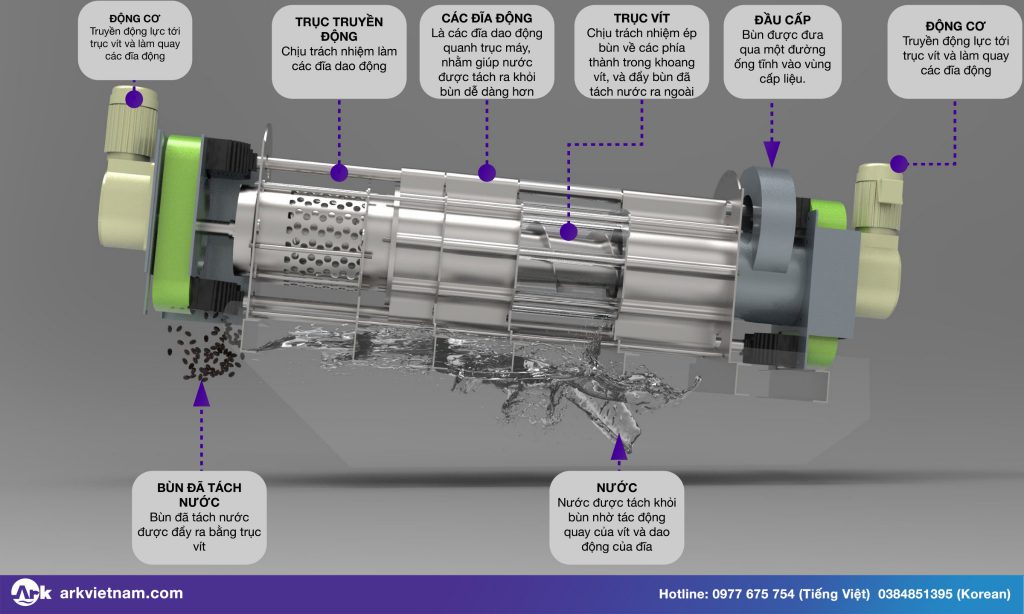

The multi-disk screw press uses the pressure of the multi-disk system and the screw blades. The multi-disk system separates the water and the sludge.

KS-ST type construction

The sludge-polymer reaction tank has a circular design, with overflow valves (anti-spill valve) and an agitator system. That smart mechanism is suitable for wastewater with sludge concentration below 1%. Firstly, the tank will concentrate sludge to a concentration of 2 - 3.5%. It ensures the screw could press sludge.

An integrated filter system inside the ST round tank could extract a large volume of water. The agitator system can adjust the speed depending on the type of sludge. The goal is to optimize the reaction to precipitate floc.

KS-RT type construction

There is no above-mentioned water filter mechanism. RT sludge-polymer reaction tank is square. They are suitable for wastewater with a higher concentration of suspended solids than the ST type.

Principle of operation

The body has the same design in both ST and RT types. The body has a tapered screw with spiral screw, fixed rings, movable rings, and a filter tube. The fixing rings are bolted to the four fixed bolts. The moving rings are linked to the transmitting shaft. The screw is driven by two motors and two gearboxes.

By this innovating design, the screw has no friction with the rings (fixed and movable). Therefore, the screw is not corroded. ARK screw press machines have a longer lifetime than older generations on the market. At the same time, the screw and the rings can automatically clean, avoid congestion.

After precipitation, liquid sludge from the reaction tank is fed into the screw. The distance between each screw groove (pitch) becomes smaller and smaller towards the end of the screw. The pressure increases, sludge is pressed harder and becomes drier. At the same time, water is discharged from the gap between the moving rings and the fixed rings.

Applicability multi-disk screw press

ARK Việt Nam Multi-disk screw press is suitable for many types of wastewater, such as:

- Food processing: seafoods, livestock and domestic water treatment.

- Processing vegetable oils such as pressing peanut oil, coconut oil, extracting coconut milk ...,

- Textile dyeing, paper production, plating, plastic production, cosmetics, ceramic tiles, mining ...,

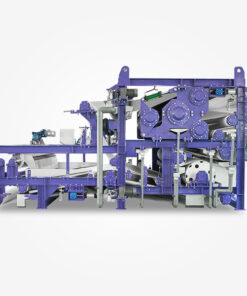

Multi-disk screw press has more applicability. They suit a wider application range than belt-press and filter-press.

In addition, ARK Vietnam also provides a type of screw press that does not use any gearbox. It only has one motor with old technology that causes the screw to be corroded by frequent friction with the washers, this type has code is SV-RT. This product's advatage is cheaper, however the lifetime will be shorter.

Why use Dewatering screw press (multi-disk type)

Advantages

- Screw press uses modern technology. Improved sludge-polymer reaction tank can handle wastewater with too low sludge concentration. The machine has a mechanism to filter out excessive water, providing a stable sludge. It works most efficiently while avoiding congestion.

- Outstanding improvement with two motors and two gearboxes. The screw system is minimized friction, prolonging the life of the machine.

- The rotation speed of the screw is low, so the power consumption cost is negligible. Better energy-saving than decanter centrifuge or belt-press. The self-contained structure makes it easy to clean.

- The screw press almost does not make annoying noises. They are quiet even after operating for a long time.

- The screw press can be placed in a small space. Suitable for factories with limited area.

- Easy to operate. Especially, multi screws models (such as ST/RT 203 204 … ) can be disassembled individual screws for maintenance. The remaining screws can still work normally. Customers do not have to worry about the interuption during maintenance.

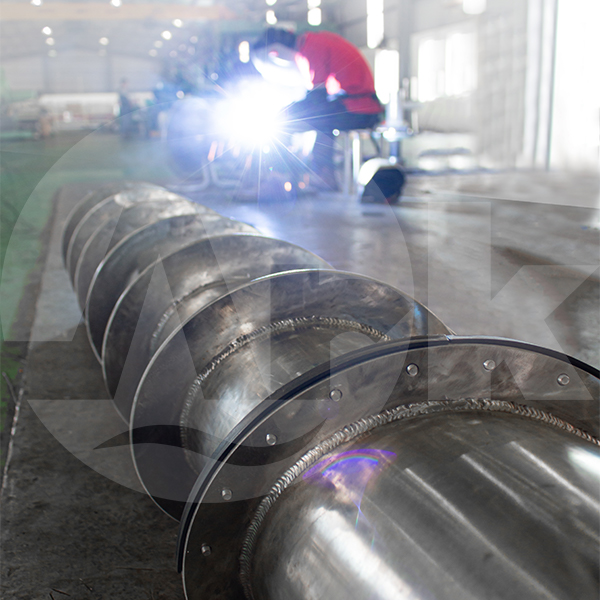

- The machine's components are all manufactured and assembled in the ARK factory in Vietnam. This results the prompt mainternance and minimize the repair time.

Benefits of multi-disk screw press

In many aspects, ARK Việt Nam multi-disk screw press possesses outstanding advantages. The screw and reaction tank are fine-tuned, which leads the machine can work continuously and durably. The screw components and disks are all fabricated from STS304 stainless steel, non-corrosion.

Moreover, the machine has a self-contained structure, easy to operate and clean. The cost of the screw press is easily affordable. We have many models which are suitable for different volumes of wastewater. The most notable economic benefit is that the machine consumes very little electricity. No annoying noises during operation. The machine allows customers to replace and upgrade without affecting the whole system.

Auxiliary equipment

ARK Vietnam's screw presses are intelligently designed. The machine has a closed mechanism, including the feed reactor. For the rest, the machine needs quality polymers to work effectively. Therefore, ARK provides our customers with sludge treatment polymers at favorable prices. Sludge conditioners, coagulants, acids, alkalis, flocculants, etc. are available in large quantities.

Quality guarantee and after-sales service

The prestige and efficiency of customers are always our top priority. Choose to buy multi-disk screw press, customers will be released from the concern of the expensive costs incurred. In addition, ARK has a professional team, support the customers throughly since machine's purchase and aftersale stage.

ARK owns core Multi-Disk Screw Press technology. ARK directly design, fabricating and supply the sludge dewatering machine in our factory in Vietnam. We provide consultant service to help customer to choose the most suitable model. Further is the test run, operation traning after the machines installation.

If you have any questions about the design of your sludge treatment system, use the state-of-the-art multi-disk screw press. Please contact us immediately for enthusiastic advice, 24/7. We'll help you!

Thành Chung –

Very good. People should buy models which have more than two screws to backup.

saeed –

thanks