In ARK Vietnam, the installation and repair process of the decanter centrifuge is always the fastest and most accurate. Spareparts replacement is genuine and timely when choosing ARK Vietnam's products. Our engineers will give detailed installation drawings to help the customer visualize the overall structure.

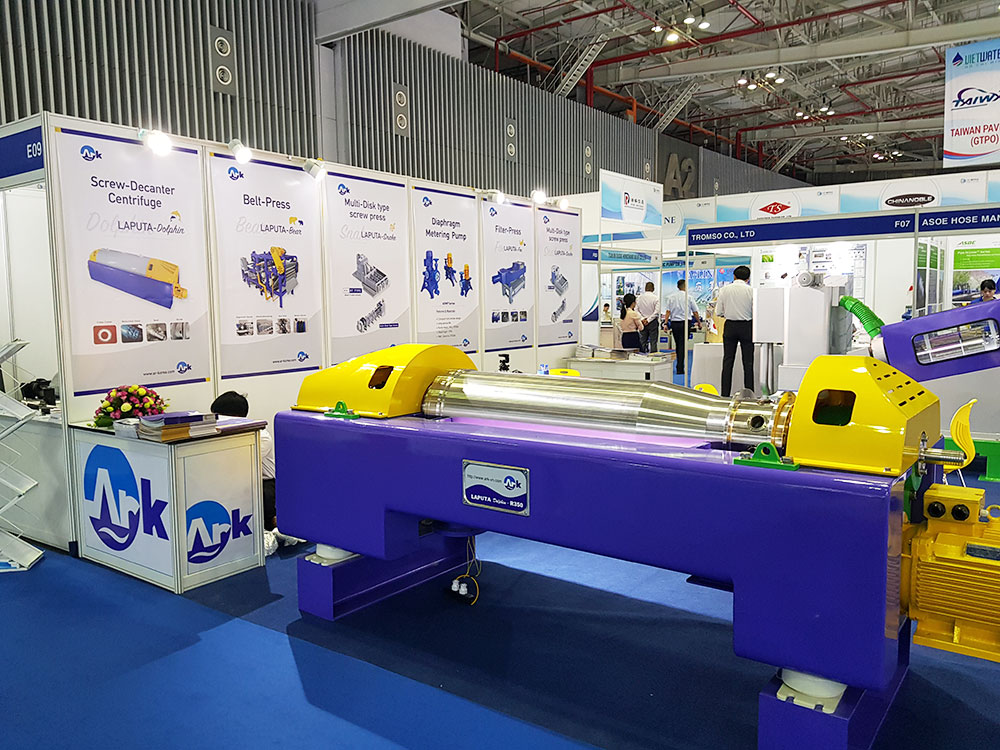

Decanter Centrifuge is a kind of sludge press that is popular in industrial plants, which is an important step in the wastewater treatment system. With the advantage of modular design, easy to disassemble. The machine operates continuously (loading in - discharging) following to a closed process. High specific efficiency with many types of sludge of the food, seafood processing, textile, and dyeing industries ... Bringing absolute safety, minimizing odors in the process of wastewater treatment. Especially with its compact design, it saves a lot of installation space.

Quality assurance, stable operation

Decanter centrifuge has the function of separating two basic components of the sludge solution. It's water and mud. Many investors choose centrifuges for the sludge filtration system because of its advantages. It is better than traditional types, such as filter-press or belt-press.

The liquid sludge will be pumped into the rotating drum inside the machine from an input. This part gradually increases the rotational speed, creating a larger centrifugal force. The sludge has a higher density than water, so it will splash into the drum and stick to it. Wastewater escapes through holes arranged thickly on the rotating cage. The sludge is retained and is twisted by a central screw (which rotates at a much slower speed than the drum) and discharged sludge by a cake outlet. Workers can use bags, use chutes to transport sludge to the specified place. Dispose, destroy or reuse according to the needs of the business.

All stages of production, processing and set up are extremely meticulous, strictly under ISO standards

Installation machine for the project

Decanter centrifuges are developed based on the principle of separation by the specific gravity (relative density) of fluids. Provides a better cost solution, improves reliability, and simplifies operation. The machine is highly durable and has low maintenance costs. The actual implementation is not too complicated. The operation of the machine is done with simple guidance, with full instructions from the manufacturer.

- Provide all necessary specifications and specific technical drawings for the construction unit.

- Materials are manufactured with the best wear-resistant materials. For example, 304 stainless steel has high hardness.

- Precision machined and assembled. For the rotation process not to be eccentric, creating vibrations.

- Low energy consumption. Still maintaining high performance with continuous working.

A 3D rendering, describe the machine installation position in the sludge treatment system

Image of project after successful set up

Quick repair process

After many years of operation, decanter centrifuge will occur some problems, requires replacement of accessories or repair of some parts. Especially in many production fields, wastewater contains many corrosive chemicals such as acids, alkalis, solvents, plating, detergents, textile dyeing, etc., which reduces the machine's lifespan due to chemical corrosion. With thoughtful after-sales service, we collect customers' feedback throughout the process of using the device. From there, update the damage status and plan the fastest repair.

Please contact us immediately for an enthusiastic and fast consultant.

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.