There are many kinds of sludge dewatering machines in the market, the most popular should be belt-press and filter-press, following are more modern models like screw-press, decanter centrifuge. Each type of machine has its own advantages and disadvantages. ARK Vietnam would like to provide some information for customers to choose the right product.

Product quality and price are decisive factors for investors. Quality and price will vary from different manufacturers.

On the market today, there are 4 popular types of sludge presses including decanter centrifuge, screw press, belt-press, and filter-press. Criteria for choosing the right sludge dewatering machine such as type of sludge, sludge characteristics, quality of sludge press, supplier, machine price ... (see more Criteria for an effective selection of sludge dewatering)

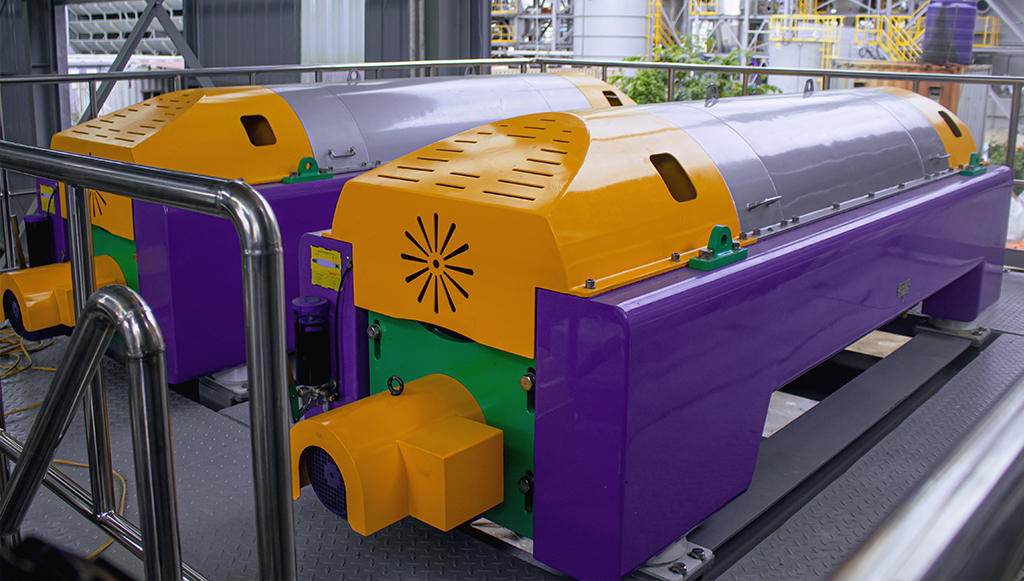

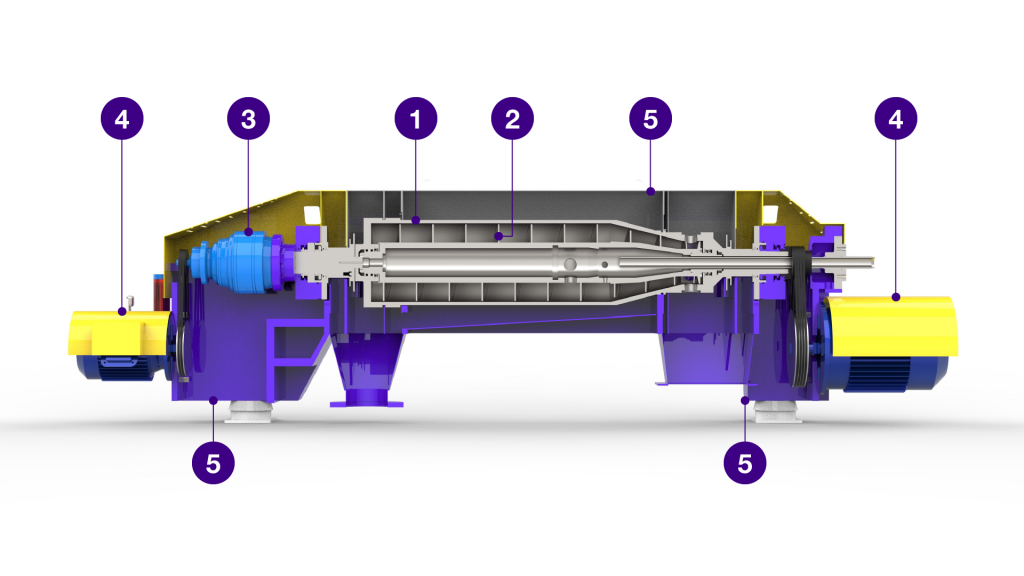

I. DECANTER CENTRIFUGE

Decanter (Decanter Centrifuge Dewatering Machine) is the most advanced sludge treatment equipment today. It is manufactured by many brands, such as ARK Vietnam. ARK is confident to be the only company that directly manufactures decanter centrifuge in Vietnam.

A decanter centrifuge includes a rotating platen, a rotating screw (have same shaft but different speeds), a transmission box, a The main body of the machine is compact, but the rotation speed of the centrifugal shaft is very high (3500 rpm). The device has a closed structure and is easy to clean after use.

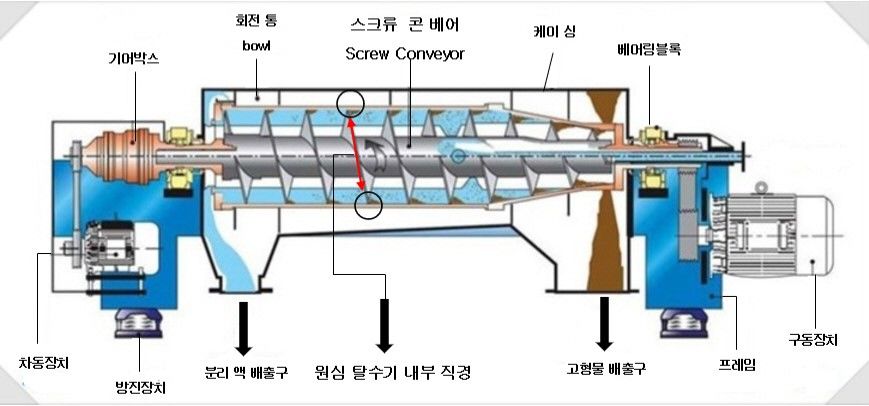

1.1. Mechanism

The flocculated sludge is fed into the body, the solid phase and the liquid phase are separated under the centrifugal force. Under the difference in shaft rotation speed, the whole solid is extracted. The water and sludge are discharged on two different outputs.

Structure diagram of decanter centrifuge

1.2. Pros - Cons

Advantages

- The machine has a compact structure. Save space for installation

- Large capacity

- Saving-water for cleaning

Disadvantages:

- Installation and operating costs are quite high. Equipment consumes a lot of electricity and chemicals.

- The device may make loud noises. Maintenance is quite complicated and requires a skilled team to handle the problem.

1.3. Application of Decanter centrifuge

Decanter centrifuge usually used in the wastewater treatment system for domestic/industrial. In particular, the device can handle livestock farm waste.

The cost depends on the amount of sludge to be treated, which will have an appropriate capacity. The difference in price between models is from $10,000 to $40,000.

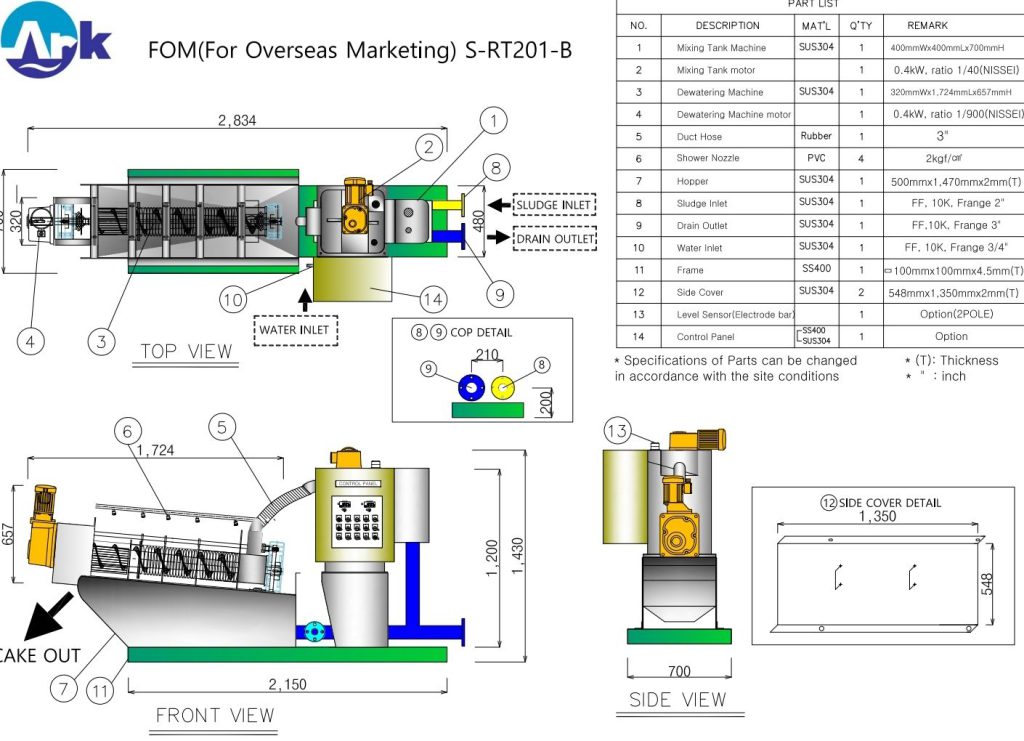

II. SCREW PRESS

Screw press (Multi-disk type screw press Dewartering machine) It is a new generation sludge press with many outstanding functions. Suitable with various types of sludge, widely used in sludge treatment.

2.1. Structure of screw press

Structure diagram of screw press, type SV-RT

The main parts of screw press include a screw, filter, sludge-polymer reaction tank, and body. The machine has a compact structure when combining a sludge-polymer reaction tank and a dewatering unit. In addition, the closed structure makes the equipment more durable and easy to maintain.

2.2. Mechanism

The inlet sludge is concentrated and pressed to dewater at the same time. The filter section consists of movable rings and fixed rings that perform the function of flipping the sludge and separating the sludge from the water. The filtered sludge is then moved and pressurized by a rotary screw, which is dried out by the discharge outlet. The liquid phase is separated by gravity between the gap of two adjacent discs.

2.3. Pros and cons

Advantages

- The flocculation unit (sludge-polymer reaction tank) is better for low concentration sludges (including viscous sludge). Can reduce sludge moisture better than other sludge presses with same capacity.

- Consumes less electricity, chemicals and washing water.

- The noise level is low (less than 60bB) and has less vibration than the decanter centrifuge.

Disadvantages:

- Only suitable for small and medium-scale systems.

2.4. Application of Screw press

The screw press is used with different types of sludge. Even high-viscosity sludge such as food processing, milk production, etc.

The screw press has 3 types: S-ST, S-RT, and SV-RT. The price of SV-RT is considered the cheapest and widely used in Vietnam. The difference between the three types at the same capacity is from $3,500 - $10,000.

III. BELT PRESS

Belt-press (Belt Press Dewatering Machine) is a sludge treatment equipment that has appeared for a long time and is trusted by many investors. The machine has a simple structure, easy to use and maintain. The device can change the moisture content of the sludge when adjusting the conveyor.

3.1. Structure of Belt-press

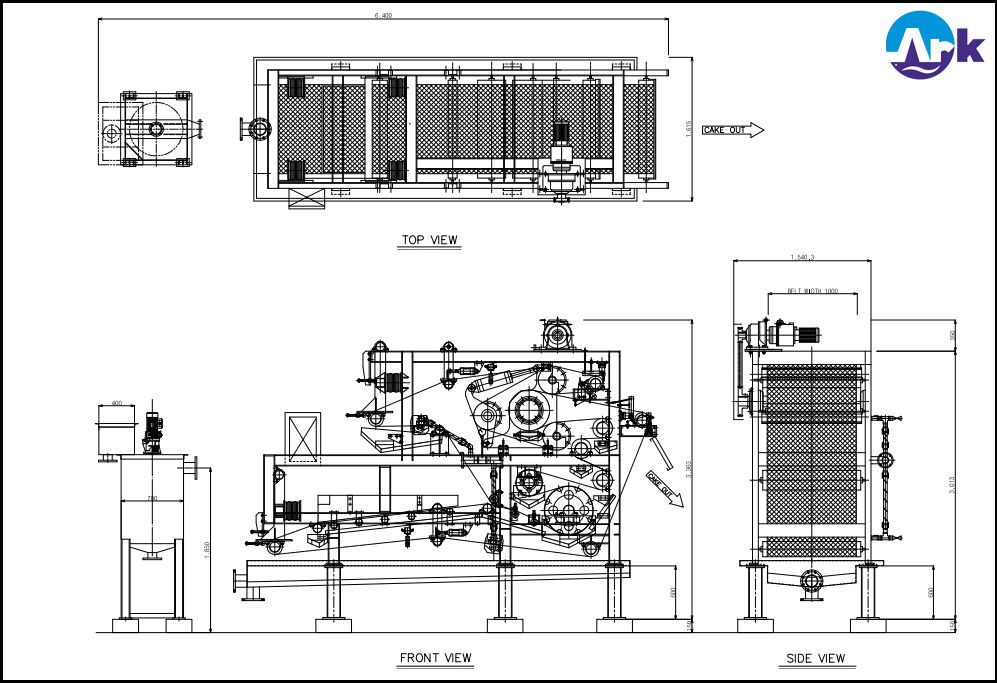

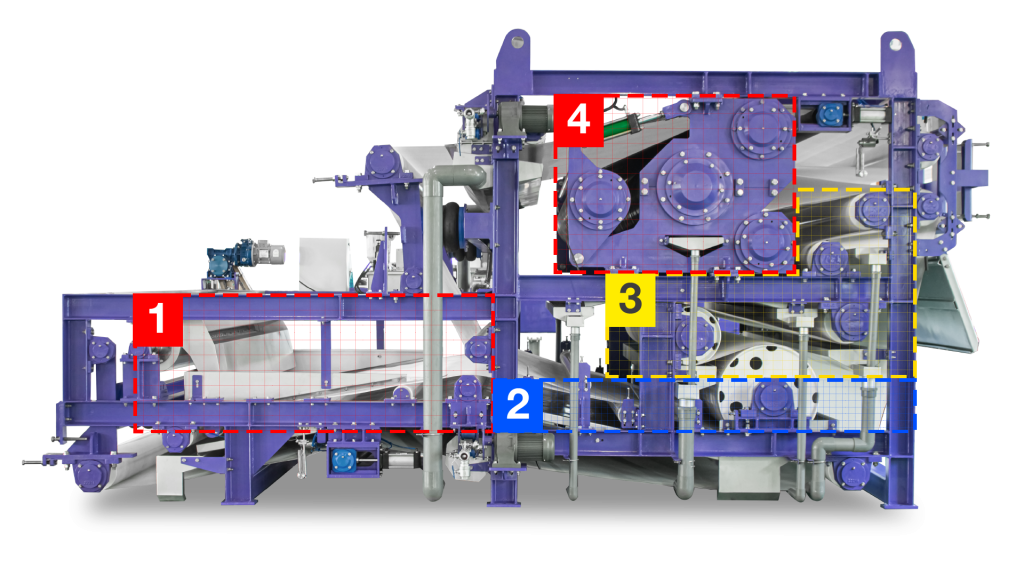

Structure diagram of belt-press

Belt press consists of main parts such as rotating belt, sludge pressing roller between upper and lower belts, machine body. The belt-press is designed with the sludge-polymer reaction tank separately. It has an open structure. The machine has many auxiliary devices such as gears, high-pressure washing system. In addition, it is large in size and weight.

3.2. Mechanism

Flocculating sludge is fed into the space between two different belts. The belts press sludge by high-pressure which is created from multiple rollers.

3.3. Pros and cons

Advantages

- The price of belt-press is cheaper than other dewatering machines.

- Save energy and chemicals

Disadvantages:

- Use a lot of water to clean

- Make loud noises

- It is necessary to replace the filter cloth periodically. Adjust conveyor belt tension to ensure pressing efficiency.

3.4. Application of Belt-press

Belt-press is widely used for a long time. Due to its low cost and especially suitable for sludges that require not too high dryness. Some industries often use belt-press such as pulp and paper industry, domestic wastewater treatment system, etc.

Belt-press is cheaper than other sludge dewatering machines. The difference between models with different capacities is about $ 7,000 - $ 10,000.

IV. FILTER PRESS

Filter-presss (Filter Press Dewatering Machine) is a sludge treatment machine that produces a high dry sludge cake. The device saves a lot of collection and transportation costs. Selected by many investors for small and medium-scale processing systems.

4.1. Structure of Filter-press

Filter-press consists of the following main parts: a hydraulic cylinder, a drip tray, plates, and frames. Filter-press is designed separately with a sludge-polymer reaction tank and has an open structure. The machine is designed with many auxiliary devices.

4.2. Mechanism

Coagulated sludge (depending on the type of sludge that requires or does not require the use of polymers) is fed into frames and pressurized. Sludge is continuously pumped until all frames are full. The machine will stop at that time. The sludge is dewatering under pressure from the hydraulic cylinder. The fenders move in opposite directions on a steel frame that holds the sludge. Filter-press works in batch for about 4-5 hours/batch.

4.3. Pros and cons

Advantages

- The sludge cake after pressing has a high level of dryness. It helps reduce collection costs.

- Consumes fewer coagulant chemicals.

- Low noise. Save cleaning water.

Disadvantages:

- Not suitable for large scale factories with large volume of sludge

- Need workers to supervise

4.4. Application of Filter-press

With a simple mechanism, filter-press is very effective with many types of sludge such as sewage sludge from textile and dyeing production, iron and steel production, etc. However, due to limited batch operation, it is not suitable for a large volume of sludge.

Filter-press has an average price with the difference between models ranging from $5,000 to $10,000..

For advice, selection, and quotation of suitable sludge dewatering machine, investors should pay attention to:

- Type of sludge (for example: septic tank, sewage sludge of industrial/domestic, feed water treatment system, paper production ...)

- Characteristics of sludge (flow, sludge concentration)

- Processed time in a day (for example, 8 hours for administrative units, 24/24 hours for industrial private units ...)

- The price is in line with the quality

- Prestigious sludge press supplier

- After-sales service. Guaranteed commitment

- When an incident occurs, the supplier must be present in time. Repair and fix quickly.

Today, many brands provide the above types of sludge presses. However, ARK Vietnam is the only unit capable of producing all kinds of sludge presses with favorable prices.

ARK Vietnam Co., Ltd – Prestigious sludge press supplier

30 years of experience

With 30 years of experience in Korea and 10 years in Vietnam, ARK always aims for sustainable values, accompanying customers.

Modern production line

Our production line follows the most modern technology in Korea, imported directly from the US, UK, Korea. Ensure ISO 9001:2015 standards.

Skilled staff

ARK has a team of highly qualified engineers with many years of experience. Skilled workers always try their best to bring top-quality products.

International and domestic distribution

ARK's sludge dewatering machines are not only trusted in Korea and Vietnam but also selected by other countries. The reliability of ARK has been proven by positive customer reviews.

Our commitment

ARK Vietnam is committed to bringing 100% brand-new products, according to Korean technology, produced in Vietnam directly. We are always ready to provide the machine and support in time. In addition, every customer wants to try ARK's sludge press honestly, and see their economic benefits. We have a service to test run for all types of sludge.

Please contact us immediately for an enthusiastic and fast consultant.

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.

We are looking for a screw press of capacity 2.5 m3/hr for 20hrs operations. Sludge consistency chemical 2% (vol 35m3) and biological 1% (vol 7m3). (Textile unit)

Thank you for choosing the ARK Vietnam screw press!

We will work with you via email before you leave. Please check your email for more information.