The paper production industry in Vietnam is developing with hundreds of factories. Along with the great benefits of that industry, its wastewater is also a challenge for business owners and authorities. Although the waste sludge of paper production is not difficult to handle, it is necessary to use the right type of sludge press to achieve the highest efficiency.

Properties of waste sludge of paper production

The sludge from the wastewater treatment system of pulp factories is a solid waste of large volume, recovered from the pulp and paper production process. In addition to other mechanical impurities, sewage sludge always contains a large mass of shredded fibers.

Wastewater treatment system of paper recycling

Types of sludge generated in the paper production

It can be used directly or converted into high-value products. Depending on the origin of the fibers in the sludge, the pulp containing sludge is classified into:

- Primary sludge: Formed during the production of primitive wood pulp;

- Deinking sludge: recovered from the deinking process of recycled paper;

- Secondary sludge: obtained from the paper recycling wastewater treatment process.

Total sludge can account for 3-5% of total paper production. The cellulose fiber content can account for 40-60% of the solid mass.

Treatment of sludge generated in the paper production

Primary sludge can be reused by recovering the pulp through the DAF (Dissolved air flotation) tank. Pulp recovery and reuse to avoid waste of resources is always a priority. Particularly for deinking sludge and secondary sludge, it is necessary to use mechanical equipment for treatment before collection. Then transported sludge to the specified place. There are many types of sludge presses on the market today. However, choosing the right type of sludge press for the paper industry is not easy. Because of the below problems:

- Does the sludge dewatering machine work effectively?

- Is the machine durable?

- What price?

- How long to install?

- Is the operation complicated? Does it take a lot of labor?

- Warranty and maintenance?

With such a series of questions, investors will take a long time to choose. Let ARK introduce and compare the most suitable sludge presses for the paper industry:

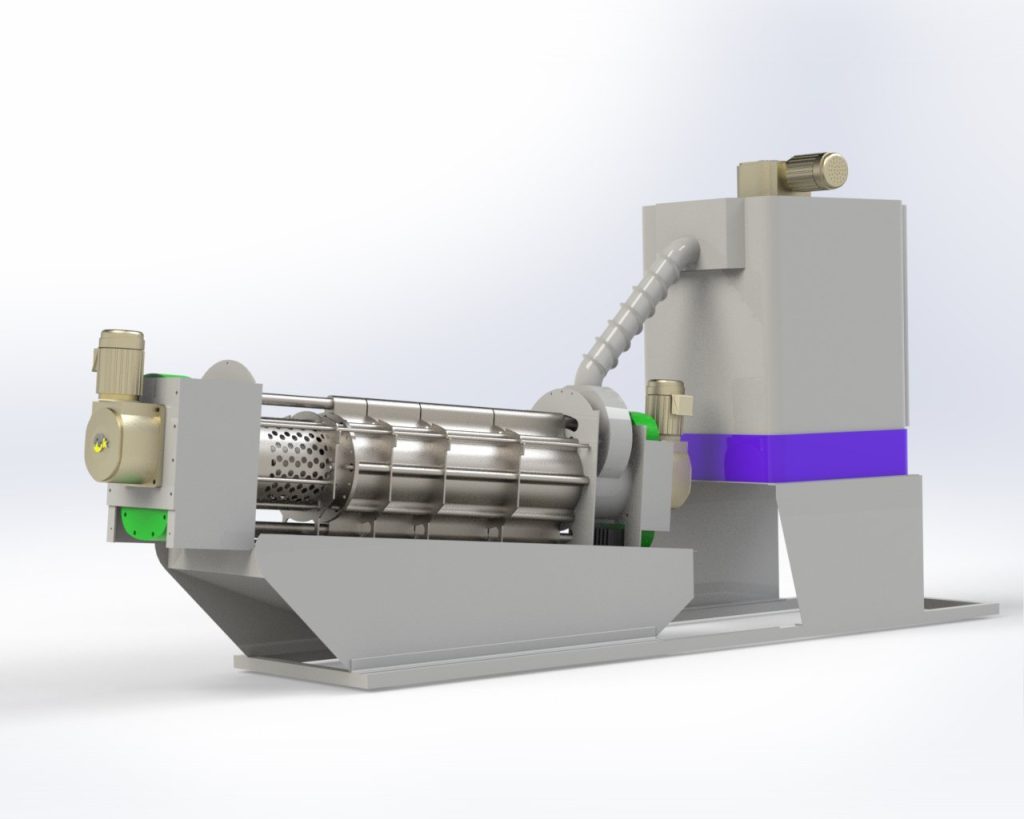

Decanter Centrifuge

Decanter Centrifuge is a kind of sludge press that is popular in industrial plants, which is an important step in the wastewater treatment system. With the advantage of modular design, easy to disassemble. The machine operates continuously (loading in - discharging) following a closed process. High specific efficiency with many types of sludge of the food, seafood processing, textile, and dyeing industries ... Bringing absolute safety, minimizing odors in the process of wastewater treatment. Especially with its compact design, it saves a lot of installation space.

Decanter centrifuge has the function of separating two basic components of the sludge solution. It's water and mud. Many investors choose centrifuges for the sludge filtration system because of its advantages. It is better than traditional types. The liquid sludge will be pumped into the rotating drum inside the machine from an input. This part gradually increases the rotational speed, creating a larger centrifugal force. The sludge has a higher density than water, so it will splash into the drum and stick to it.

Wastewater escapes through holes arranged thickly on the rotating cage. The sludge is retained and is twisted by a central screw (which rotates at a much slower speed than the drum) and discharged sludge by a cake outlet. Workers can use bags, use chutes to transport sludge to the specified place to dispose or destroy.

Screw Press

Screw press is a device used at the end of the wastewater treatment process. The screw press can be used to replace the sludge tanks or thick sludge tanks. Reducing the cost of building treatment tanks for treatment plants.

The working principle of the screw press is to use special spiral screws. It allows the dehydration and is automatically cleaned, avoiding clogging. Controlled by an automatic operating system. Using new technology can replace traditional machines such as belt-press, filter-press. These types need to use high-pressure water to clean filters or conveyors, which is very water-intensive. This cleaning mechanism is ideal for removing sticky and clogging sludge.

In addition, the screw rotation speed is very low (from 2-4rpm). Therefore, the cost of electricity used is also very low (0.8kW/h). It also consumes less water than decanter centrifuges. The noise level of the machine is also very low, only 63dB after 1-2 years of operation.

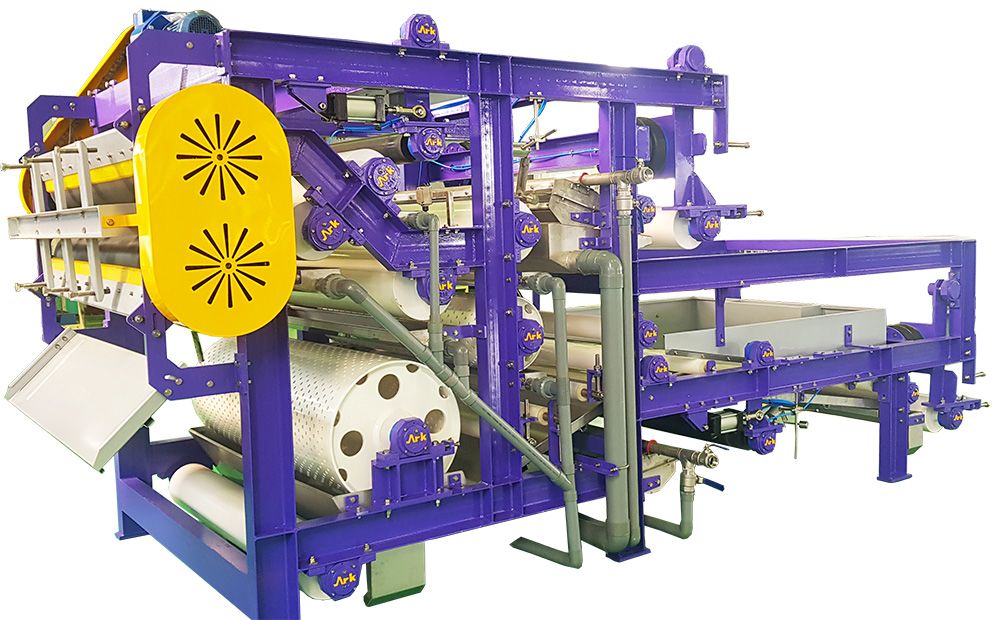

Belt Press

This is a new type of sludge dewatering that operates on the principle of using the pressure of the rollers on the conveyor belt. The sludge is pressed into thin, firm sheets that dry very quickly. Clean water is discharged through the conveyor belt and out. Belt-press is a continuous sludge dewatering. Medium economic efficiency for factories that do not require too low humidity.

Compare the advantages and disadvantages of different types of sludge presses for the paper industry

Among the four most popular types of sludge presses today. The pulp and paper industry should choose the above three types of sludge presses that will give the most suitable sludge drying.

| Type | Decanter Centrifuge | Belt-press | Screw press |

|

|

|

|

| Humidity of sludge after pressing | 70 - 85% (stable humidity during operation) | 75 - 85% (humidity may change when adjusting the conveyor belt) | 70 - 85% (stable humidity during operation) |

| Operation | 24/24, less labor requirement | 24/24, need workers to monitor regularly | 24/24, less labor requirement |

| Price | high | low | medium |

| Maintenance | easy maintenance | regular maintenance, because the conveyor belt will reduce filter pressure after a while | easy maintenance |

Currently, paper production companies still prefer belt-press because of its cheaper price. And the requirement of the sludge dryness after pressing is not too high. However, Decanter centrifuge and Screw press with high technology will give the pressed sludge a more stable moisture content. Accompanied by higher economic efficiency.

To choose the right sludge dewatering, please contact ARK Vietnam today for the fastest advice and quote.

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.