Treatment of wastewater, livestock, and poultry waste is an urgent need of livestock farms. Wastewater has an unclean smell, affecting people and the surrounding environment. The high content of organic matter and eutrophication is a heavy pollutant for the surrounding areas. Therefore, it is necessary to apply radical treatment measures, including the application of mud presses.

In 2020, the Department of Livestock Production (an agency under the Ministry of Agriculture and Rural Development) orients that Vietnam's livestock industry will grow by about 4%. Meat output of all kinds reached about 5.5 million tons. Pork about 64-67%, poultry about 25-27%, grass-fed cattle 9-11%. Egg production reached 14.5 billion eggs and about 1.2 million tons of milk.

Components and properties of wastewater and livestock waste.

Sources arise mainly from livestock bathing water (swine, cow), feces, urine, and leftovers.

Livestock wastewater contains a lot of bacteria, pathogens, helminths, eggs (spores), and larvae, ... extremely affecting human health if in direct contact. In addition, this type of wastewater also cause odors, and soil and water pollution.

➜ Example: Foot-and-mouth virus can survive from 100 to 120 days, and helminth eggs can survive for 5-6 months.

On average, each day a pig (swine) excretes about 2 liters of urine and 2.7 kg of feces. Including 70-80% protein, amino acids, cellulose, fat, and carbohydrates. The rest are salts, urea, ammonium, chloride, SO42-, sandy soil... top levels of nitrogen and phosphorus (similar to wastewater from the aquaculture industry).

Waste water/animal waste applies which standard?

According to QCVN62-MT:2016/BTNMT (applies to wastewater from pigs, cows, chickens, shrimp, fish, ...), the permissible threshold values of the parameters in livestock wastewater is:

|

Order |

Parameter | Unit | Value A |

value B |

|

1 |

pH | – | 6 – 9 |

5.5 – 9 |

|

2 |

BOD5 | mg/l | 40 |

100 |

|

3 |

COD | mg/l | 100 |

300 |

|

4 |

total suspended solids | mg/l | 50 |

150 |

|

5 |

Total Nitrogen (in N) | mg/l | 50 |

150 |

|

6 |

Total Coliform | MPN (Most probable number) or CFU (Colony Forming Units) /100 ml | 3000 |

5000 |

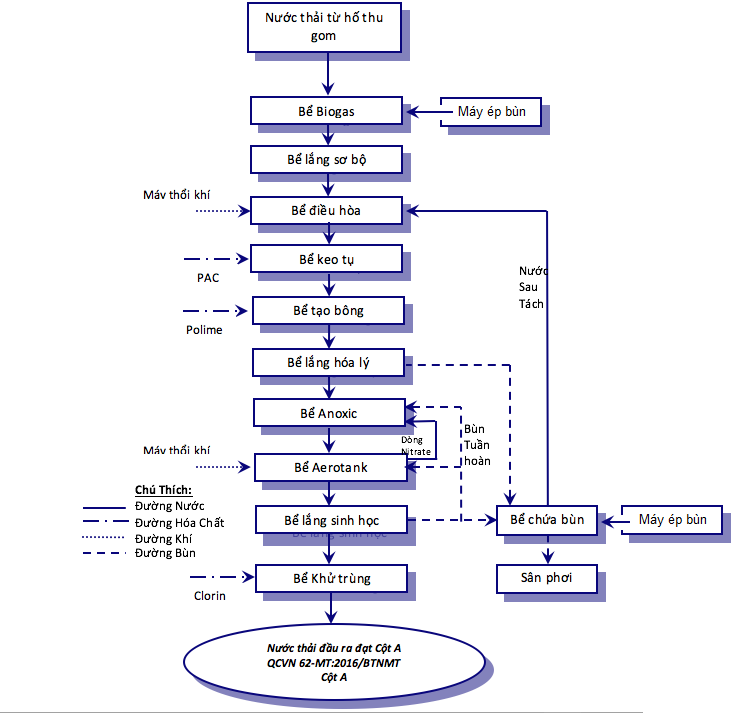

Process of treating wastewater and livestock waste

The basic livestock wastewater treatment process in Vietnam includes the following steps:

- Separation of feces

- Biogas

- Chemical and biological treatment.

- Discharge into the environment or reuse

- Separation and pressing of feces in wastewater

1. Separation of stools

Right from the first stage, the sludge dewatering machine has shown its usefulness. Farms often use different sludge dewatering machines, screw press, decanting centrifuge, etc.

ARK Vietnam we specialize in distributing and manufacturing all above type of sludge dewatering, with various capacity versions. With the same advantage of technological lines according to Korean standards, we have a processing and assembly factory right in Vietnam.

- sludge dewatering machine will almost completely separate solid manure from wastewater.

- Reducing the concentration of pollution in wastewater, saving the cost of building treatment systems.

- Take advantage of fertilizer production.

- Minimize the number of water components, reducing the volume and volume of waste. Reduce transportation costs and storage area.

2. Biogas

Biogas technology is based on the activity of anaerobic microorganisms.

Biogas tanks help incubate livestock waste and decompose it to create gases such as methane (CH4), CO2, N2, H2O, H2S. In which CH4 can be used as gas, cooking, drying, and generating generators. Helps save fuel.

➜ Note: gas H2S generated causes corrosion of gas pipelines, so it needs to be removed.

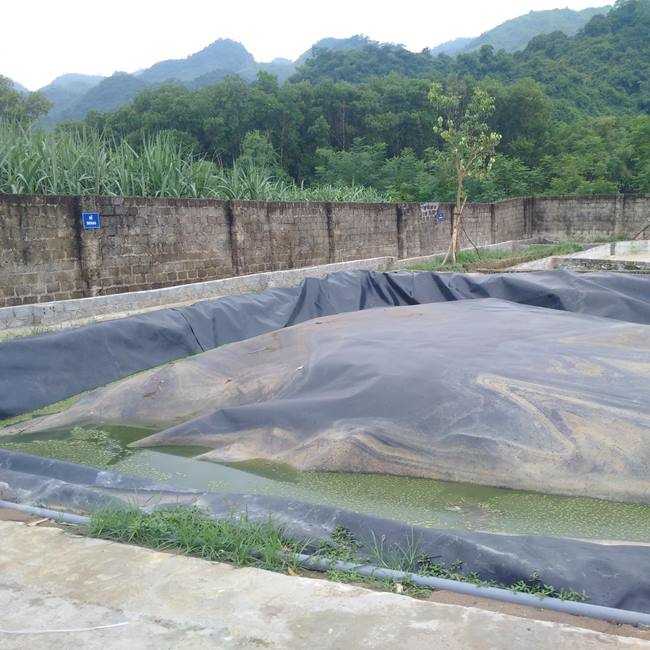

If the farm is large, the waste is high, and the volume at birth is high. The biogas tank will be designed by covering with tarpaulin HDPE (High-density polyethylene) waterproof, instead of concrete.

3. Anaerobic treatment

If not using biogas tank, anaerobic system UASB (Upflow Anaerobic Sludge Blanket) will be the application.

In terms of structure, the UASB tank is a treatment tank with a sludge layer on the bottom. With a separation and gas collection system, the treated wastewater will come out at the top. The anaerobic microorganisms present in the sludge will decompose the organic matter present in the wastewater. The gas is collected and returned to the tank.

➜ See more: Learn more about wastewater and sludge treatment in the seafood industry

The denitrification process

In the UASB tank system, the anoxic tank takes place in the nitrification process, reducing nitrogen gas, N2O or NO. These gases escape from which nitrogen is removed.

NO3– → NO2– → NO(g) → N2O (g) → N2 (g)

Some species of nitrate-reducing bacteria used include: Bacillus, Pseudomonas, Methanomonas, Paracoccus, Spirillum, Thiobacillus, Achromobacterium, Denitro bacillu, Micrococus, Xanthomonas.

NO3–– + 1.08 PM3OH + 0.24 H2CO3 → 0.056 C5H7O2N (represents bacterial cells) + 0.47 N2 + 1.68 H2O + HCO3–

NO3–– + 0.345 C10H19O3N + H+ + 0.267 NH4+ + 0.267 HCO3– → 0.612 C5H7O2N (representing bacterial cells) + 0.5 N2 +2.3 H2O + 0.655 CO2

|

Advantages |

Disadvantages |

|

|

4. Air conditioning tank

The conditioning tank has the effect of regulating the flow, concentration of pollutants, and neutralizing pH.

5. Aerobic treatment

The aerobic biological tank will be the next stage that determines the treatment efficiency of the entire system. The remaining organic matter will be decomposed into the atmosphere.

Ammonia will be converted to nitrate with the help of 2 strains of microorganisms Nitrosomonas and Nitrobacter. Biomass produced by microorganisms will become sludge in settling tanks.

NH4+ + 2 O2 → NO3– + 2 H+ + H2O

4 CO2 + HCO3–– + NH4+ + H2O → C5H7O2N (bacterial cell, produces biomass) + 5 O 2

6. Coagulation and flocculation tank

Wastewater is then pumped through the flocculation tank, and coagulant chemicals (such as PAC, polymer PAM) are added in combination with the stirring system. Concentrations of PAC or PAM should be calculated accordingly, avoiding under or excess.

Nhờ có các chất keo tụ mà các chất lơ lửng kết dính với nhau tạo thành những bông cặn lớn, dễ lắng xuống đáy bể lắng, tách ra khỏi nước thải.

7. Physical and chemical settling tanks and biological settling tanks

The coagulation will arise and continuously increase the amount of sludge. Sludge is collected in settling tanks and brought to sludge storage tanks.

8. Disinfection

After undergoing biochemical methods, livestock wastewater still contains about 105-106 bacteria in 100ml of water. Chlorine will be injected into the water. This is a strong oxidizing gas that destroys metabolic processes, leading to the destruction of microorganisms.

9. Finished Lake

Formulated to remove toxic byproducts from chlorination of water before being released into the environment or reused in livestock.

Sludge treatment, livestock waste

The amount of sludge generated from the settling tanks will be stored in the sludge tanks before pressing. The traditional method is to use a sludge drying yard. However, this is an outdated method and takes up a lot of space.

Sludge dewatering once again plays its role. Especially the sludge dewatering products of ARK Vietnam give the finished sludge with impressive dryness and stable performance.

Advantages of sludge presses in wastewater and livestock waste treatment

- Dispose of waste of time without causing blockages or stagnation. Does not affect the environment. Reduce the risk of diseases for livestock and poultry.

- Labor cost savings compared to sludge drying or filter press method. Inefficient working capital. Reduce the impact on human health. Save transportation costs, save water, and improve economic efficiency.

- Tiết kiệm chi phí vận chuyển, tiết kiệm nước, nâng cao hiệu quả kinh tế.

- Simple and automatic operation mechanism. The sludge dewatering can be easily upgraded, without affecting the entire system.

The application of sludge dewatering to wastewater and livestock waste treatment brings high and long-term economic benefits. Customers need advice on the right type of machine, with a detailed quote. Please contact ARK Vietnam immediately for timely support.

When choosing ARK Vietnam, you will never be disappointed

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: [email protected]

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.