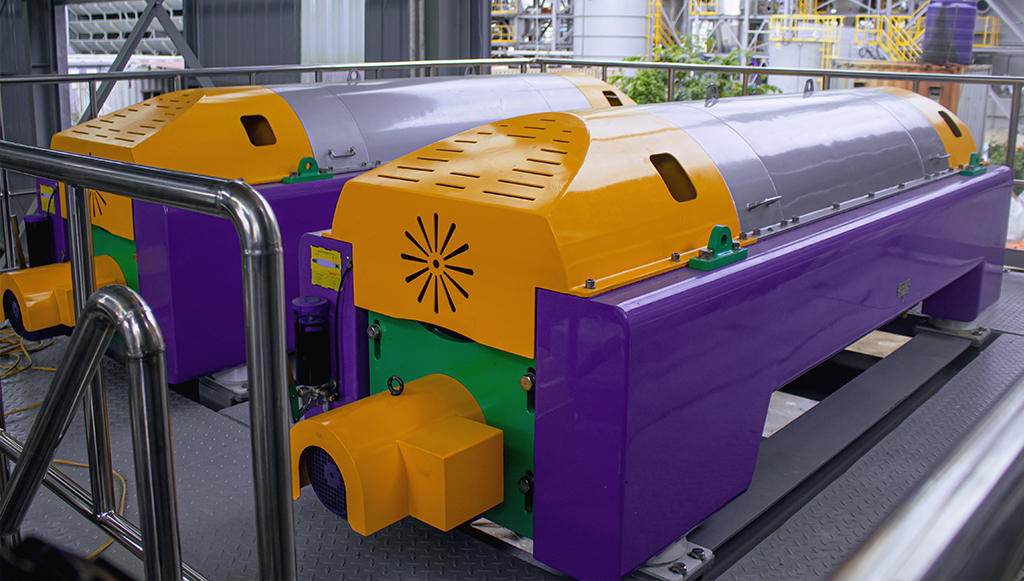

The Decanter centrifuge is the most modern sludge dewatering equipment available today. At ARK Vietnam, the machine is researched and manufactured based on advanced technology lines with a completely new design. The product is the perfect piece for a complex wastewater treatment system.

Coming from South Korea, we inherit the scientific and technical achievements of developed countries, with many years of experience in the field of waste treatment. Set foot on the S-shaped land in 2011. ARK is proud to be the only enterprise, manufacturing and assembling centrifugal slurry presses in Vietnam according to Korean standards.

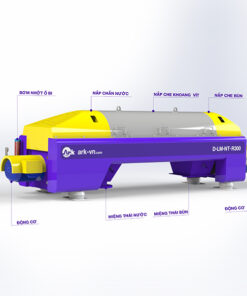

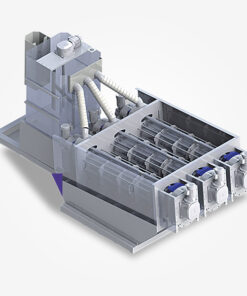

Overview of Decanter Centrifuge

Decanter Centrifuge is ARK Vietnam's flagship product with the best current technology, materials, and features. Equipment meets the needs and satisfaction of domestic and international customers.

| Warranty | Lên đến 12 tháng |

| Rotational speed | 1200 – 4000 rpm |

| Maximum capacity | 70m³/hr |

| Sludge concentration | 1% ~ 2.5% |

| Design | Compact, space-saving design |

| Suitable for | All kinds of sludge |

| System | self-contained, automatic |

| Efficiency | stable sludge |

The machine has the shape of a smart Dolphin, the centrifuge decanter has a compact design that does not require much space and is durable for continuous operation.

Machine parts are designed from the best materials, anti-wear and resistant to corrosive chemicals, and easy to replace and maintain because ARK is manufactured right in Vietnam.

Decanter centrifuge is suitable for most wastewater treatment systems: food processing, pharmaceuticals, water supply and drainage, physicochemical industry ..., with a large amount of sludge.

Structure and working principle

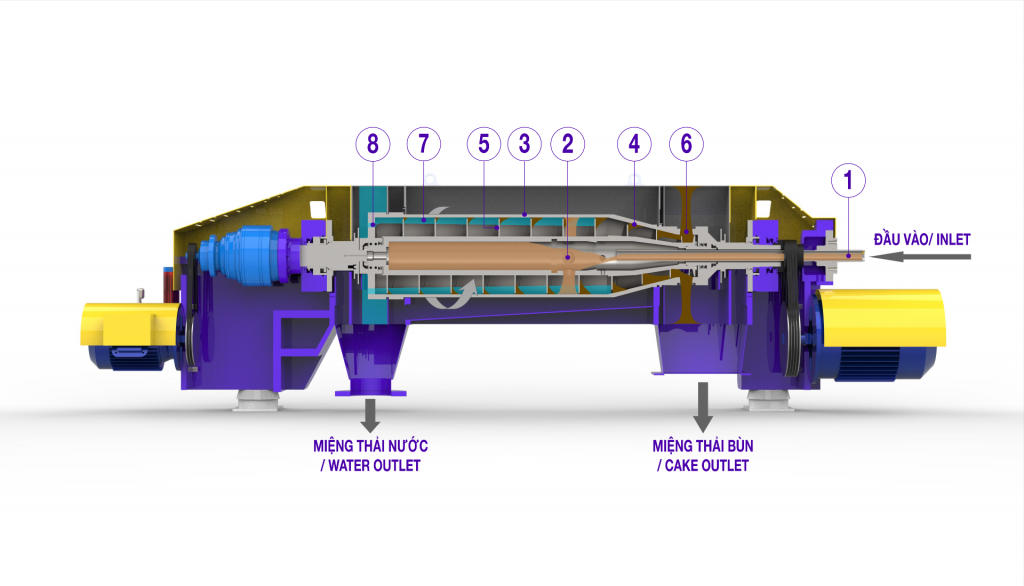

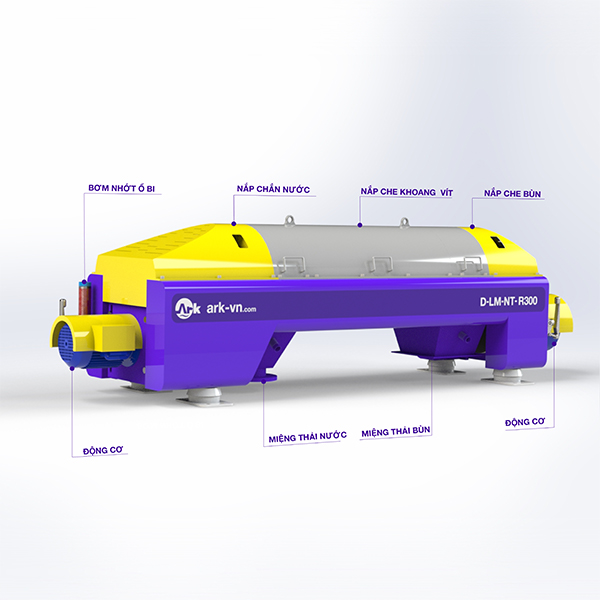

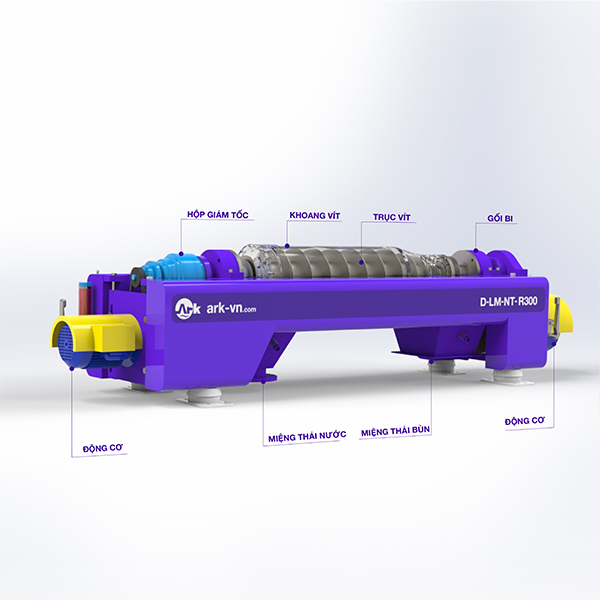

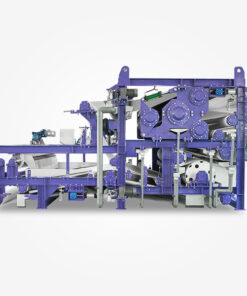

Decanter Centrifuge Structure

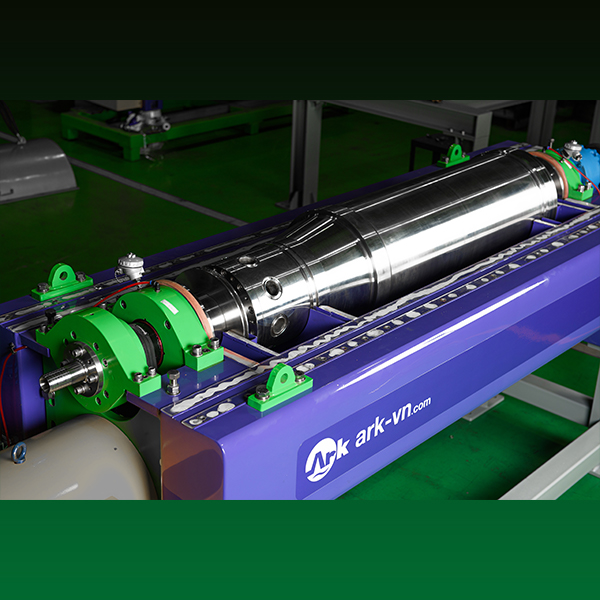

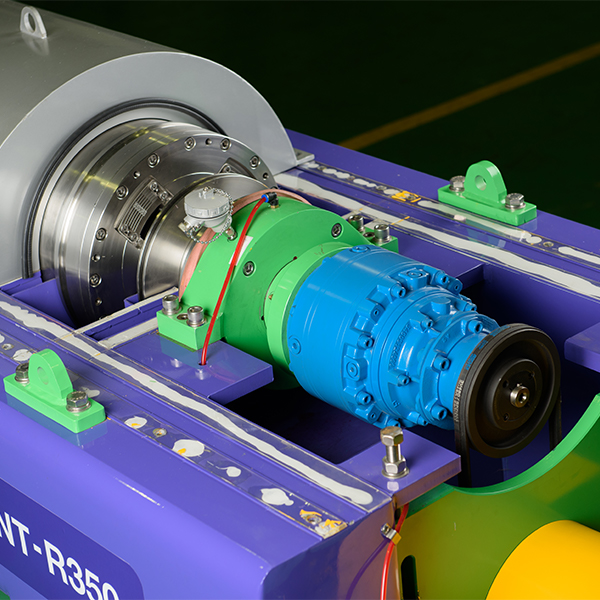

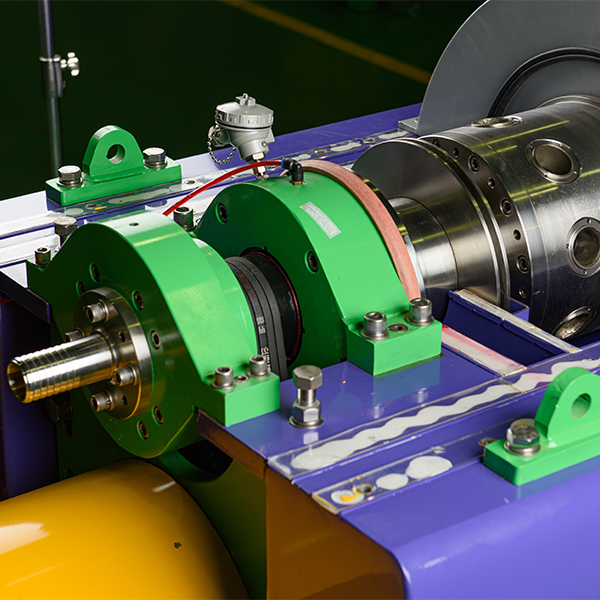

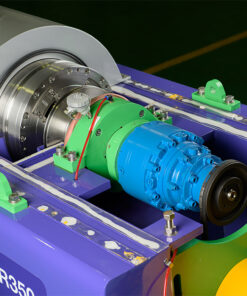

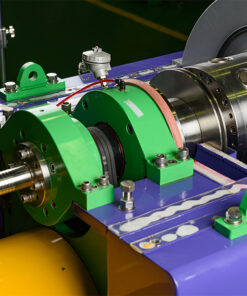

The machine is composed of a centrifugal cavity and a coaxial rotating screw. They are driven by two motors that rotate at different speeds.

Annotation of Decanter Centrifuge parts:

- Lubricant oil pump (1)

- Cover of the reduction gear (2)

- Cover of the screw cavity (3)

- Cover of the ball bearing (4)

- Sub-motor (5)

- Main motor (6)

- Ellastic support (7)

- Water outlet (8)

- Machine body (9)

- Sludge discharge mouth (10)

- Lubricant oil pump 2 (11)

- Gear box (12)

- Ball pillow (13)

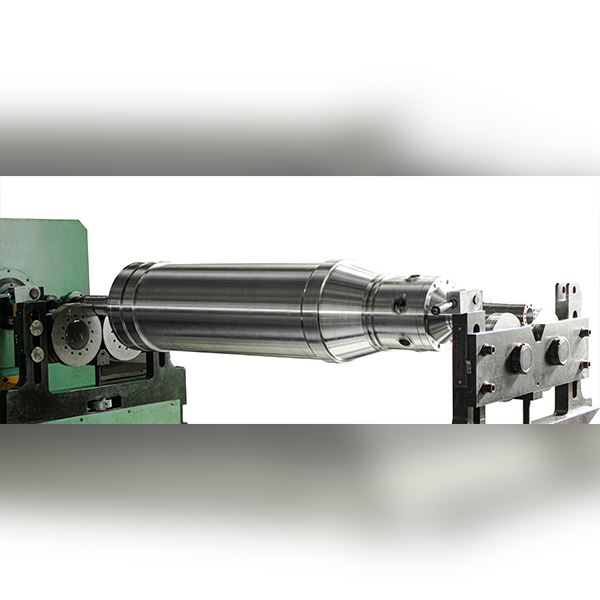

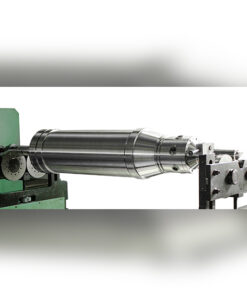

- Screw (14)

- Centrifugal chamber (15)

- Ball pillow 2 (16)

Decanter Centrifuge Operation Principle

Stage 1: Prepare polymer solution

ARK Vietnam not only manufactures sludge dewatering equipment such as Decanter Centrifuge, but also provides polymers. Before running the machine, we need to prepare the polymer solution. The solution is mixed in a certain ratio that depends on the sludge properties.

The mixed ratio needs to be calculated by testing with wastewater first. To observe the reaction time and the level of sludge floc formation.

Stage 2: Pumping sludge into the machine

The sludge, after being mixed with the polymer solution (1), is pumped through the inlet. DECANTER CENTRIFUGE. From there, the mixture will enter the centrifuge chamber along the sludge supply shaft and exits via oulets (2) on the sludge supply shaft body to the centrifuge chamber.

Annotate:

- Sludge solution mixed with polymer solution (1)

- Sludge outlet (2)

- Centrifugal chamber (3)

- Dewatered sludge (4)

- Screw (5)

- Sludge outlet of centrifugal chamber (6)

- Water is separated (7)

- Drain outlet of centrifugal chamber (8)

Stage 3: Sludge enters the centrifuge chamber (3)

Centrifugal chamber has a cylinder/cone, that rotates at a certain speed to optimize dewatering. The sludge rotates with the centrifuge cavity to form a concentric layer on the wall of the centrifuge chamber.

The solid (4) is extracted and pressed against the cavity wall by centrifugal force. The length of the cylindrical cavity and the conical angle are carefully calculated to suit specific requirements.

Stage 4: Screw processing (5)

The screw rotates at a different speed from the centrifugal chamber, responsible for transferring the dewatered solids to the top of the cone, to the sludge outlet (6) of the centrifugation chamber, and then to the sludge discharge outlet.

At the same time, the water that is separated (7) will move to the drain outlet (8) on the centrifuge chamber and splash out to the drain outlet of the machine.

The rotation speed of the screw determines the residence time of the solids in the centrifuge chamber. This time is an important factor in determining the dryness of the sludge. It can be adjusted by changing the rotation speed of the screw.

In addition, the design of the screw is based on the application and separation task. The humidity of the machine will be from 65-80%, depending on the characteristics of the input sludge.

Advantages of Decanter Centrifuge

- ARK Decanter Centrifuge inherits Korean elite technology. Materials are imported, extremely durable, precisely fabricated.

- We have assembled on high-tech lines in Vietnam, meeting ISO 9001:2015 standards. Easy replacement and repair, because we have a factory in Vietnam.

- Simple and safe operation, easy to approach. The machine can work continuously and independently.

- Smart as a dolphin. The system is completely sealed. Sludge is not splashed out, clean and odorless during operation. The machine has automatic cleaning system and shutdown timer.

- Easily adjust sludge dryness and water clarity before and during operation. The machine has a minimalist design that does not require much space.

- Sludge from Decanter has the most stable moisture content above all sludge dewatering, from 65 to 85%.

- Suitable with all types of wastewater with complex physicochemical properties.

Benefit of economic

In many aspects, the Decanter Centrifuge of ARK Vietnam shows outstanding advantages.

With dewatering technology using centrifugal force, the machine can handle large volumes of wastewater quickly and efficiently. We have many models with different capacities to meet all production scale from small to very large.

Reducing up to 90% volume of sludge when compared with traditional dewatering methods. That is an effective solution, saving money for customers.

In addition, labor costs are reduced, and the machine is easy to adjust the capacity and humidity of sludge.

When using ARK Decanter centrifuge, customers will save up to 90% of sludge treatment costs (by hiring third-party companies). Therefore, after 1-2 years, the initial investment of buying the machine will be recovered.

In case of expanding the production scale, customers could replace the machine easily, with no effects on the whole wastewater treatment system. It is compatible with many types of wastewater.

Auxiliary equipment for Decanter Centrifuge

Mixing tank for polymer and wastewater before pumping into the machine is not required when using the decanter. The operating system is very simple, only includes: polymer dissolving tank, pumping system, and polymer. Customers can fully take advantage of their existing polymer mixing tanks, or order polymer dissolving devices from ARK Vietnam.

ARK also provides many types of polymer for sludge treatment at favorable prices. Coagulants and flocculants are available in large quantities.

Quality guarantee and after-sales service

The prestige and efficiency of customers are always our top priority. ARK owns a team of professional technicians, dedicated to customer support before and after buying the machine. We maintain strict quality control during design and manufacturing. As well as ensuring quality standards in the wastewater treatment industry.

ARK directly supplies sludge dewatering, designs and installs the machine in the existing factory of the customer. Our service includes consultant according to the needs of the customer, help to choose the most suitable model with the best capacity. Installation, test run, and train employees of the customer. Our hotline is always available.

Customers want to buy Decanter Centrifuge. Contact us now for enthusiastic advice and instant quote, 24/7.

Fire Phoenix JSC –

Good quality, fast delivery, dedicated support, professional service.

ARK Vietnam –

Thank you for supporting ARK's decanter centrifuge

Mr Định –

Bạn lắp máy li tâm cho dự án ngành khai khoáng( Mỏ than, khai thác quặng) nào chưa cho mình xin tư liệu đề trình chủ đầu tư

ARK Vietnam –

Dạ! bên em đã triển khai máy ép ly tâm cho các dự án ngành khai khoáng rồi ạ. Bộ phận kỹ thuật sẽ liên hệ và tư vấn anh đầy đủ ạ.