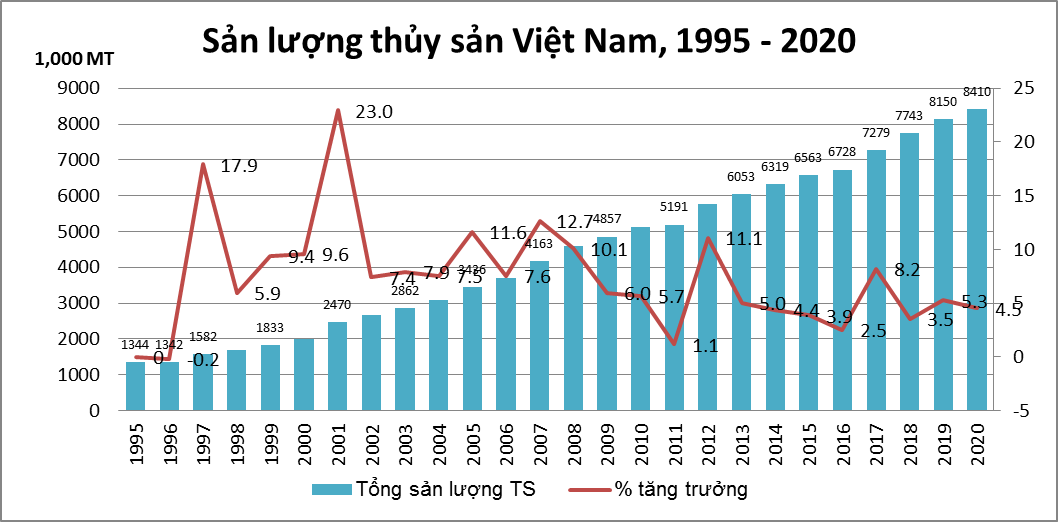

As one of the key economic sectors of Vietnam, the seafood industry contributes to 4-5% of GDP and 10% of the country's total export turnover ($8.5 billion). In 2020, the fishery output will be about 4 million tons. Of which, farming reached nearly 5 million tons.

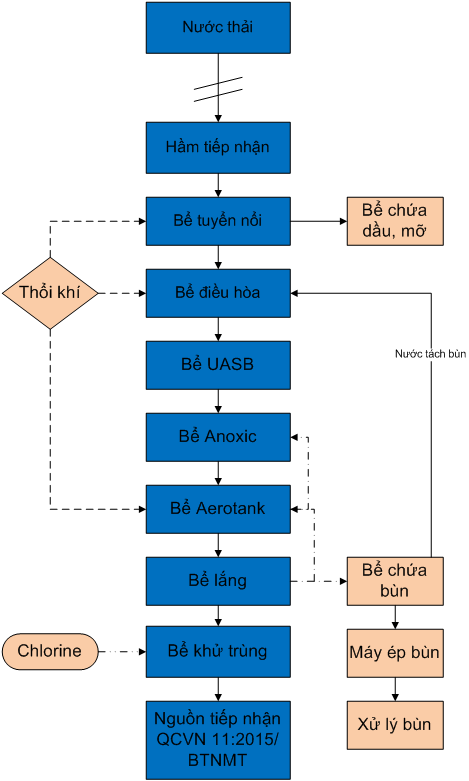

Aquatic wastewater is rich in carbohydrates, proteins, fats, etc., and when discharged into the environment, will reduce the concentration of dissolved oxygen in the water. Because organic substances are decomposed (oxidized) by bacteria, or cause the phenomenon of “algal blooms”. Leads to the suffocation of fish, shrimp, and aquatic plants.

In the previous post “Sludge presses in wastewater treatment , aquatic sludge”, ARK Vietnam introduced an overview of the wastewater and aquatic sludge treatment system. As well as the position and role of the ARK sludge dewatering in the water separation and sludge filtration stage. Bring economic efficiency to enterprises and export processing zones. This time, let's better understand the complex cycle above from an in-depth perspective.

I. What is a UASB tank?

Anoxic bioreactor (or UASB – Upflow Anaerobic Sludge Blanket) is class The most important item in the biochemical treatment stage in particular and the wastewater treatment system. This is where the most stubborn and harmful chemicals in aquatic wastewater are broken down.

UASB tanks with PVC filter media installed (Polyvinyl chloride) submerged in water. This filter layer is hollow and has a large contact surface area as a substrate for microorganisms.

Principle of operation

The UASB tank is a place to cultivate specific bacteria. They live off energy and byproducts from breaking down nitrogen and phosphorus compounds in wastewater.

Wastewater flows through microbial membranes. After a period of growth, the microbial biomass film thickens, preventing air from entering the inner layers. Without oxygen, anaerobic bacteria grow, completely breaking down organic matter into CH4 and CO2 (through acidification, acetate reaction). These gases kill aerobic students, causing their biomass film to peel off. Then it is washed away by water and settles to form sludge in the settling tank.

On the surface of the PVC filter material, a new microbial film is formed, which is in contact with oxygen. This process repeats cyclically, so BOD5 and other eutrophication are thoroughly treated.

Note

Microbial culture must be given close attention. Their number determines the maximum efficiency of the whole process. Therefore, partial sludge will be pumped back to the UASB tank to maintain the microbial concentration.

Organic matter + Anaerobic microorganisms → CO2 + CH4 + H2S + NH3 + New biomass +…

II. The effect of the air conditioner tank

The conditioning tank regulates the flow and concentration of pollutants in the wastewater before it is put into the following stages. Always have a device to blow air continuously into the tank, mixing to avoid the anaerobic phenomenon. Also, a large amount of chlorin (factory cleaning detergent) is liberated, release, free.

III. aerobic biological tank

Wastewater from the anaerobic tank will be taken to an aerobic tank, where it specializes in culturing active microorganisms in an oxygen-rich environment. Their job is to decompose the remaining organic substances in the chain reaction oxidation – remove.

Anoxic and Aerotank tanks are where the processes of nitrate reduction and phosphorus reduction take place.

- Two groups of bacteria Pseudomonas and Clostridium in a hypoxic environment, will reduce nitrate (NO3–) and nitrite (NO2––) and ammonium to gas N2, which escapes the water and goes out.

- Bacteria Acinetobacter will take part in phosphorus reduction.

Oxygen (air) is supplied to the aero tank by air blowers, which are highly efficient with air bubbles less than 10 µm. Supply gas to the tank for:

- provide oxygen for aerobic microorganisms to convert dissolved organic matter in wastewater into CO2, organic nitrogen and NH4+ to nitrate NO2–

- Mix the wastewater and activated sludge evenly. Creating conditions for microorganisms to have good contact with the substrates to be treated

- release microbial inhibitory gases.

Reaction Equation

Organic matter + O2 + aerobic bacteria → CO2 + H2O + NH3 + C5 H7O2N (represents new bacterial cells) + other product.

Intracellular Respiration: C5H7O2N (represents bacteria) + 5O2 → 5 CO2 + 2H2O + NH3 + Energy.

IV. Explain the phenomenon of flocculation and flocculation

The wastewater is pH balanced with the addition of NaOH to ensure high flocculation efficiency.

PAC – Poly Aluminium Chloride

PAC is added and mixed. This substance dissociates into Al3+ ion. Al3+ quickly converts to Al(OH)3 is a colloidal precipitate that binds suspended particles in water to form large flocs and sink to the bottom.

Al3+ + 3H2O → Al(OH)3↓ + 3H+

Polymer – Polyacrylamide

Similar to PAC but more effective, polymer PAM ability to form larger sized flocs. They are suspended in the water and are easily removed by ARK Vietnam's modern sludge presses or flotation tanks.

V. flotation tank and how it works

The surface tension of air bubbles causes flocs or solid particles to adhere to. Air bubbles rise to form a layer of mud floating on the water. This scum is easily removed.

VI. finishing treatment

1. Filter

The pressure filter tank comprises layers of materials: gravel, sand, quartz, and activated carbon. Trace elements, non-resolvable substances, and organic halogens are removed to achieve specified values.

2. Disinfection

Chemicals used for disinfection are chlorine compounds, such as NaOCl. It diffuses through the cell envelope, reacting with the cytoplasm. Destroys metabolism, and kills microorganisms.

3. Gas treatment

Gases generated from decomposition, such as CH4, are destroyed by combustion.

4. Odor treatment

The generated odor is sucked by a high-pressure centrifugal fan with activated carbon adsorbent material.

Evaluation of wastewater treatment technology, aquatic sludge

| Advantages | Disadvantages |

| High processing efficiency (reaching 98%) | Complex operation. Requires qualified operator. Microbiological tanks must be regularly monitored. |

| Capable of treating wastewater with high BOD, reducing nitrogen and phosphorus without adding chemicals. | Construction area of large items |

VII. Aquatic sludge treatment stage

At the aquatic sludge storage tank, the air is supplied to avoid odors generated by the decomposition of organic matter. Traditional methods such as mud drying yards, and old generations of mud presses, are not efficient and do not meet the production expansion plan.

An effective alternative to modern ARK sludge dewatering machine

- Screw press: closed system, effective deodorization, avoiding the leakage of aquatic sludge that pollutes the factory. Smooth operation, energy saving, automatic control, non-stop continuous operation. Save washing water, easy to replace and maintain each screw, while the other screw can still work. Avoid stagnation in production activities. Improved mechanism with separation filter system, dynamic disc system reduces friction and prolongs product life.

- High-pressure belt press: There are many improvements in durability, semi-automatic mode saves labor costs. Enhanced sludge pressing mechanism, making the mud drier and more stable.

- Decanting centrifuge: closed system, fully automatic and continuous operation. High strength, dry mud cake, stable. Diverse capacity, suitable for a good deal of sludge. Impressive durability, automatic cleaning. Compact size, easy installation, and convenient to move.

Advantages of using modern sludge dewatering ARK Vietnam

- The water content in the output sludge cake is dry and stable. The juice comes out with high transparency, easy to handle in the later stage.

- The operation is automatic, and no labor is required. Investors with little experience can still operate by themselves.

- ARK Vietnam has a domestic factory. Therefore, maintenance becomes easy and timely.

- ARK sludge dewatering use safe, environmentally friendly polymers. Save the cost of buying chemicals.

The ARK sludge dewatering is designed with a variety of capacities and can apply to:

- Factories, granaries processing frozen seafood, exporting seafood;

- Factories producing dried seafood and canned goods;

- Fish sauce production facilities;

- Aquaculture facilities with ponds, lakes, cages, etc.

When choosing ARK Vietnam, you will never be disappointed

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.