Accompanying development opportunities are environmental challenges. Wastewater from the fisheries industry contains many pollutants that are harmful to the ecosystem and human health. Therefore, investing in treating wastewater and seafood sludge is a requirement for factories, businesses and processing establishments in the industry.

Accompanying development opportunities are environmental challenges. Wastewater from the fisheries industry contains many pollutants that are harmful to the ecosystem and human health. Therefore, investing in treating wastewater and seafood sludge is a requirement for factories, businesses and processing establishments in the industry.

Overview of wastewater, seafood sludge

Stationary sources

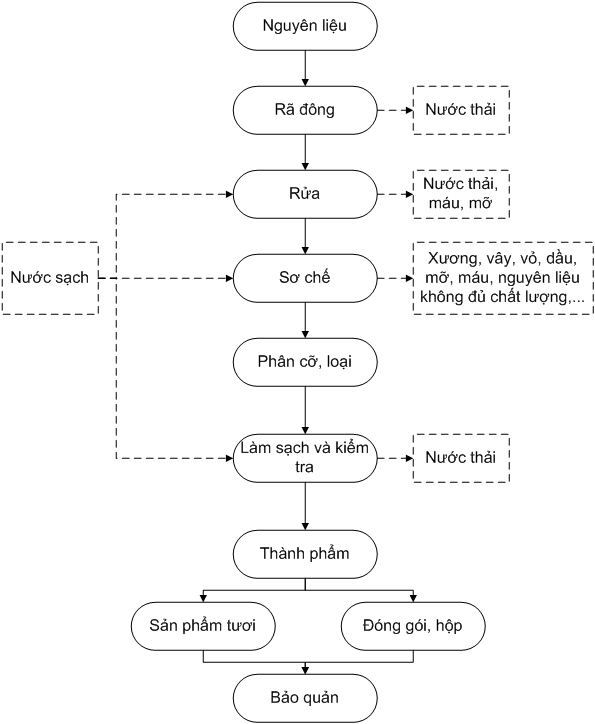

Aquaculture, exploitation, and processing include preliminary processing, filleting, freezing fish, shrimp, crab, ..., and fishmeal production, ... with diverse input materials. The stages of water change in ponds, cages, sorting, cleaning, processing, and equipment cleaning will generate a huge amount of wastewater.

Solid waste generated includes shrimp shell heads, clam shells, squid skin/shells, squid and fish organs, etc., which have an unpleasant odor, especially when decomposed.

Environmental impact if wastewater is not treated

Đặc điểm của loại nước thải này là thành phần các chất hữu cơ hòa tan, các hợp chất lơ lửng, huyền phù chứa nito, photpho, lưu huỳnh, … ở mức độ cao. Các chất này nếu thải trực tiếp ra ngoài, khi phân hủy, sẽ làm giảm đáng kể nồng độ oxy hòa tan trong nước, chết ngạt các sinh vật thủy sinh trong sông, hồ. Làm nước mất khả năng tự làm sạch, gây ô nhiễm nghiêm trọng nguồn nước mặt, nước ngầm, vùng ven biển. Các hợp chất giàu nitơ, photpho khi thải ra sông hồ làm tăng sự phát triển của tảo gây ra hiện tượng phú dưỡng hóa. Giết chết các sinh vật trong hệ sinh vật thủy sinh, kể cả các loài nuôi trồng … Các chất rắn lơ lửng làm nước đục, hạn chế ánh sáng, gây ảnh hưởng tới quá trình quang hợp của tảo, rong rêu. Chất rắn lơ lửng cũng bồi lắng lòng sông, cản trở sự lưu thông của nước và tàu bè.

Physicochemical properties of seafood processing wastewater

- 70–80% are organic compounds including proteins, amino acids, urea CON₂H₄, fats, and extremely difficult-to-process complexes.

- 20-30% comprises sand, soil, salt, additives, and detergents

- Nitrogen and Phosphorus: Aquatic wastewater contains outrageous amounts of N and P, especially phosphorus not only in the product's composition but also because of the addition of processing additives.

- COD and BOD are very high, exceeding the standard many times.

- Contains many types of bacteria, viruses, and larval eggs, helminths that cause disease. People who directly use contaminated water are at high risk of contracting dysentery, typhoid, polio, urinary tract infections, and acute diarrhea.

- Ammonia: is extremely toxic to shrimp and fish, even in tiny concentrations. The lethal concentration ranged from 1.2 to 3 mg/l.

| Targets | Unit | Concentration | |||

| Frozen shrimp | Catfish | Mixed frozen seafood | QCVN 11:2018, Cột B | ||

| pH | – | 6.5 – 9 | 6.5 – 7 | 5.5 – 9 | 5.5 – 9 |

| Chất rắn lơ lửng (SS) | mg/L | 100 – 300 | 500 – 1200 | 50 – 194 | 100 |

| COD | mgO2/L | 800 – 2000 | 800 – 2500 | 694 – 2070 | 80 |

| BOD5 | mgO2/L | 500 – 1500 | 500 – 1500 | 391 – 1539 | 50 |

| N Total | mg/L | 50 – 200 | 100 – 300 | 30 – 100 | – |

| P total | mg/L | 10 – 120 | 50 – 100 | 3 – 50 | 60 |

| Oil and grease | mg/L | – | 250 – 830 | 2.4 – 100 | 20 |

According to Vietnam Environment Administration 2009

Process of treating wastewater, seafood sludge

The current technology of wastewater and aquatic sludge treatment is very diverse and complex. Depending on the input materials and processing methods, the discharged wastewater has unique characteristics. In the final stage, most factories and factories used mud presses to treat sludge. This saves costs, takes up less area of traditional mud drying yards, and brings high efficiency.

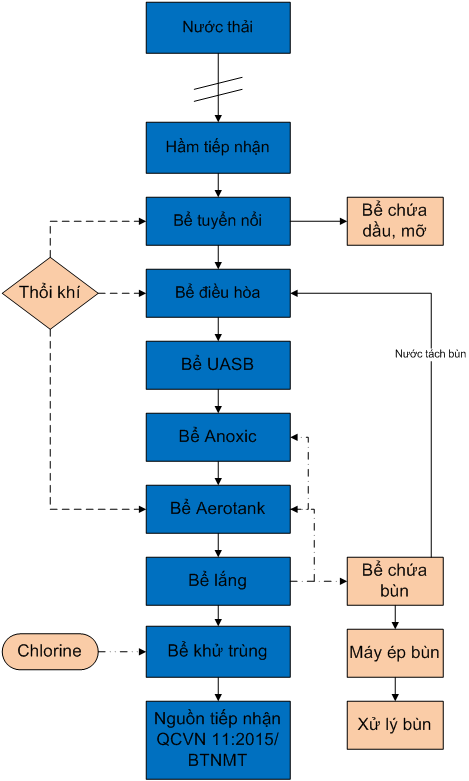

1. Wastewater mechanical treatment stage

Nước thải từ nhà máy, khu chế biến, khu nuôi trồng thủy sản được dẫn qua các song chắn rác. Rác thô, có kích thước lớn (như lá cây, xương cá, vây, vỏ giáp xác, …) bị loại bỏ trước khi chảy vào bể lắng cát. Thành phần cát sẽ được lắng lại ở đáy bể. Giai đoạn tiếp theo là bể điều hòa, nước thải được sục khí. Bể điều hòa có nhiệm vụ điều hòa lưu lượng và nồng độ các chất ô nhiễm trong nước thải.2. The stage of flotation, flocculation

Phèn PAC (Poly Aluminium Chloride) hay polymer PAM (Polyacrylamide) là tác nhân tiên quyết của giai đoạn này, các bông bùn sau khi keo tụ sẽ chảy qua hệ thống tuyển nổi. Hiểu đơn giản, khi được bơm vào, các bọt khí sẽ nổi lên mang theo váng dầu và các bông cặn lơ lửng. Hệ thống gạt ở trên bể sẽ gạn tách dầu mỡ và bùn cặn đưa về bể chứa bùn. Ngay trong công đoạn này, chất rắn lơ lửng và dầu mỡ có thể được loại bỏ tới trên 90%. Thực tế cho thấy polymer cho hiệu quả tạo keo tụ cao hơn, ARK Việt Nam hiện đang phân phối polymer PAM (Polyacrylamide) ở hai dạng: bột và nhũ tương với số lượng lớn đi kèm chiết khấu hấp dẫn.3. Biological treatment of aquatic wastewater

Anaerobic treatment

Từ bể điều hòa đến bể UASB (bể sinh học kỵ khí – Upflow Anaerobic Sludge Blanket). Các vi sinh vật kỵ khí tại đây sẽ phân hủy các hợp chất hữu cơ chứa nito và photpho. Hiệu suất xử lý COD và BOD đạt từ 60-80%. Sản phẩm của quá trình là các chất hữu cơ đơn giản như metan (CH4), nước, CO2, H2S.Anaerobic microorganisms + Organic matter → CO2 + CH4 + H2S + new biomass

Aerobic treatment

Các cụm bể anoxic và aerotank là giai đoạn tiếp theo. Các quá trình xử lý tổng hợp như: khử BOD, nitrat hóa, khử amoni và khử nitrat thành khí nitơ, khử photpho được diễn ra. Các hợp chất hữu cơ cứng đầu còn lại trong nước thải được vi sinh vật hiếu khí oxy hóa thành CO2, nước. Người ta thường tái sử dụng bùn thải hoặc bùn hoạt tính đặc biệt chứa vi sinh vật để tăng hiệu quả xử lý. Nồng độ bùn hoạt tính dao động từ 1000 – 3000 MLSS mg/L (MLSS là Mixed liquor suspended solids hay hỗn hợp chất rắn lơ lửng). Nồng độ bùn càng cao, tải lượng chất hữu cơ càng lớn. Oxy được cấp liên tục vào bể nhờ hệ thống thổi khí. Đường kính bọt khí lý tưởng vào khoảng 10 µm. Oxy là cần thiết để cho các vi sinh vật hoạt động. Hệ thống khuấy xáo trộn đều để tăng diện tích tiếp xúc. Sau bể aerotank, bể lắng 2 (lắng sinh học) là nấc thang tiếp theo phải bước. Bùn sinh ra từ sinh khối của vi sinh vật cũng như các chất lắng cặn được giữ lại ở đáy bể lắng. Lượng bùn hoàn lưu một phần về bể aerotank. Phần còn lại được đưa vào khu vực xử lý bùn.4. The stage of Physico-chemical treatment of aquatic wastewater

The water after being separated from the sludge becomes clear and harmful dissolved substances have been removed to the maximum. In the next stage will be disinfected with chlorine or ozone. After the re-measurement of chemical indicators, water can be discharged into the environment or reused for production.5. Aquatic sludge treatment stage

The sludge from the settling tank and the UASB tank is put into the sludge storage tank. Although it's called mud, the key ingredient is still water. Therefore, the sludge has an enormous volume and volume. If the production scale of the seafood processing plant is large, then the sludge storage tank needs an enormous capacity. If not handled in time, it will cause congestion and stall the operation of the whole factory. → This is where sludge dewatering machines can go mainstream. See more: Sludge dewatering machine – a great assistant for industrial wastewater treatmentBenefits of sludge dewatering machine in aquatic sludge treatment

Phương pháp sử dụng sân phơi bùn rõ ràng đã quá lỗi thời trong tình hình hiện nay. Khi mà sản lượng khai thác ngày càng tăng, đi kèm với quy mô của các nhà máy, khu chế xuất, chế biến thủy hải sản liên tục được mở rộng. Thị trường của các doanh nghiệp Việt Nam không còn bó hẹp trong nước, mà còn thu hút sự quan tâm của các đối tác quốc tế. Do đó khối lượng bùn thải phát sinh ngày càng nhiều. Thuê các đơn vị xử lý, hút bùn bên ngoài chỉ là biện pháp tình thế. Tính về dài hạn, chi phí hàng năm thực sự là một con số khổng lồ. Thay vào đó, đầu tư nâng cấp hệ thống xử lý nước thải, ép bùn hiện đại sẽ là khoản đầu tư có tầm nhìn chiến lược, và thu về lợi nhuận kinh tế lâu dài. Máy ép bùn sẽ lọc tách phần lớn nước khỏi dung dịch bùn, giảm thế tích và khối lượng bùn. Qua đó giúp giảm số chuyến phải vận chuyển, giảm lượng bùn phải xử lý. Tức là tiết kiệm tiền cho nhà đầu tư. See more: Why investment in sludge dewatering purchasing is right and profitable?Limitations of the old method

- The sludge drying yard is extremely space-consuming, depends on the weather, and causes odors and environmental pollution. Not to mention the need for a lot of workers and losing workers' health.

- Generations of sludge dewatering are old, outdated, inefficient, or congested. Regular repairs, causing production delays.

- The filter press operates intermittently. It is extremely difficult to remove the mud manually, as well as the hard, water-consuming cleaning.

- The belt press is bulky, taking up a lot of factory space. Causes unpleasant odors during operation. Cost of operating labor and washing water. Regularly have to align the conveyor belt and replace the cumbersome and strenuous filter.

Works alternative to Sludge dewatering ARK Vietnam modern

- Screw press: closed system, effective deodorization, avoiding the leakage of aquatic sludge that pollutes the factory. Smooth operation, energy saving, automatic control, non-stop continuous operation. Save washing water, easy to replace and maintain each screw, while the other screw can still work. Avoid stagnation in production activities. Improved mechanism with separation filter system, dynamic disc system reduces friction and prolongs product life.

- High-pressure belt press: There are many improvements in durability, semi-automatic mode saves labor costs. Enhanced sludge pressing mechanism, making the mud drier and more stable.

- Decanting centrifuge: closed system, fully automatic and continuous operation. High strength, dry mud cake, stable. Diverse capacity, suitable for a good deal of sludge. Impressive durability, automatic cleaning. Compact size, easy installation, and convenient to move.

Dedicated after-sales service, 24/7 customer care

In particular, the repair and maintenance process of ARK Vietnam is extremely prestigious and fast. We have a factory right in Vietnam. Application of machinery line completely imported from Korea. Replacement parts are always available, reducing waiting time for customers.

When choosing ARK Vietnam, you will never be disappointed

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.