Wastewater treatment of thermal power plants is not a minor challenge for power generation enterprises. While providing enough electricity to the people, it also ensures that the discharged water does not pollute the environment.

Composition of wastewater from thermal power plants

In producing electricity, a certain amount of waste is also generated. Sources of wastewater generated from this process include:

- Cooling wastewater: Polluted wastewater has an oil film floating on it. Wastewater from ash slag and equipment washing water has high turbidity, large sediment content, and contains metal ions.

- Domestic wastewater: This wastewater contains organic substances from the toilet including carbohydrates, proteins, lipids, etc., which are easily decomposed by microorganisms. In addition, wastewater also contains suspended substances, many nutrients N, P, easy to cause eutrophication, seriously affecting water quality.

- Wastewater from cooking activities: This wastewater contains high levels of organic matter, containing grease, minerals, ammonium, detergents, etc.

Wastewater from power plants usually has an average pH of about 6.5 – 8.5. In order to avoid polluting the surrounding water environment, it is necessary to have a scientific wastewater treatment system to ensure that the output water is really safe for the ecosystem.

See more: Safe and effective treatment of textile dyeing wastewater

Treating wastewater from thermal power plants is popular today

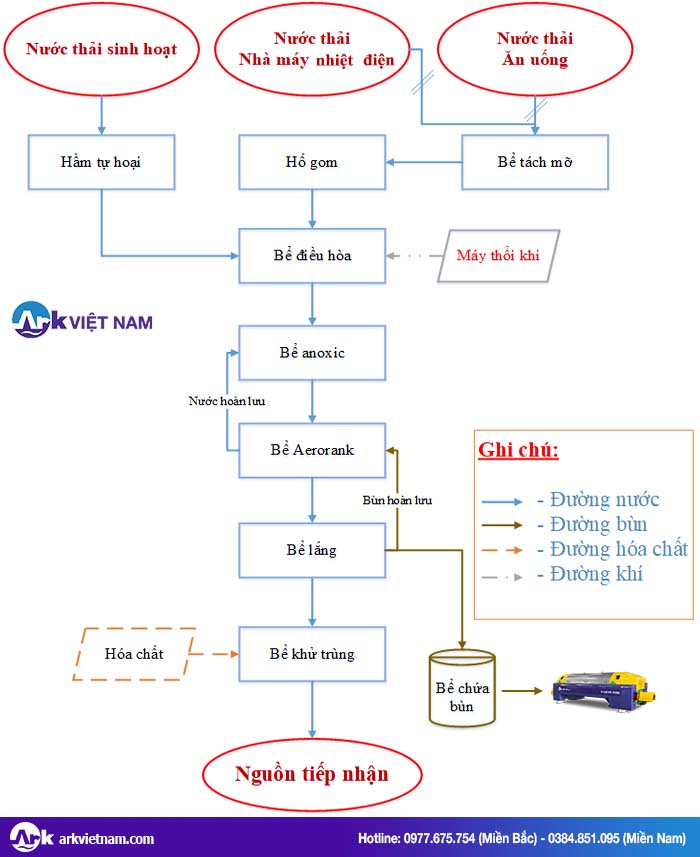

The solution to treat wastewater from thermal power plants will be implemented in 5 steps:

1. Collection tank

First, wastewater will be collected by pipeline and brought to the collection tank. In this tank, garbage screens will be installed to remove large-sized waste sources. This will avoid clogging the pipeline in the following steps.

In addition, water containing grease will be transferred through a separate pipeline to separate field grease when transferred to the collection tank.

2. Air conditioning tank

After removing a large amount of garbage, the wastewater will be transferred to the conditioning tank to stabilize the water volume and prepare to move to the next stages.

The conditioning tank is designed with an air-blowing system or a mixer. This device is installed to disturb the flow, oxidizing organic substances and especially avoiding the growth of anaerobic bacteria. This will help prevent the creation of unpleasant odors.

3. Biological treatment tank

Stage three wastewater after being conditioned will be transported to the biological tank. In this process, there will be a combination of anaerobic and aerobic treatment. This should remove nitrogenous compounds present in the wastewater.

The microorganisms in the tank will take advantage of the organic substances in the wastewater to make food. Then, it will decompose them to reduce the concentration of pollution to the lowest level.

4. Settling and sterilization tanks

Wastewater after going through the above 3 steps will still have a bit of sludge remaining. So they will be transferred to the settling tank and disinfected. This tank will help obliterate harmful substances, bacteria, and viruses. Ensure safe output water for the environment, ecosystems, and people.

5. Thermal power plant wastewater treatment sludge dewatering machine

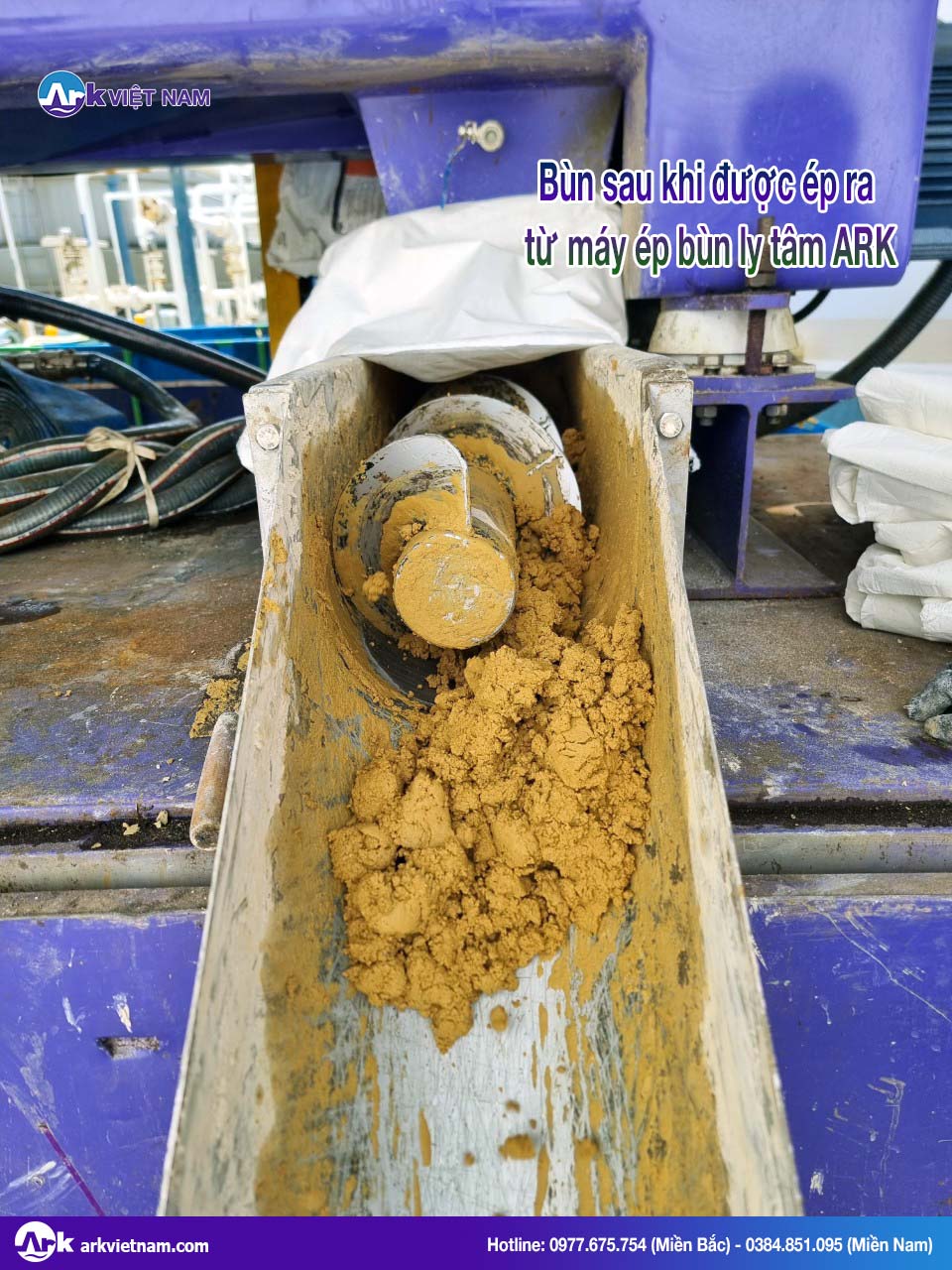

The collected sludge will be collected in the settling tank and connected to a dedicated mud press. Here, the solid will be completely separated from the water. The water after separation will be removed from most of the harmful substances.

Some pictures show that ARK's DECANTER CENTRIFUGE works very well in squeezing sewage sludge from the wastewater treatment area in the thermal power plant:

Epilogue

Nước thải từ nhà máy điện rất ô nhiễm và ảnh hưởng nhiều đến môi trường xung quanh khu vực nhá máy. Vậy nên nếu xử lý hiệu quả lượng nước này sẽ mang lại những lợi ích nhất định:

- Đảo bảo được độ an toàn cho công nhân tại nhà máy và người dân khu vực xung quanh.

- Trả lại nguồn nước sạch, tinh khiết cho thiên nhiên.

- Bảo vệ môi trường, hệ sinh thái phát triển.

- Thúc đẩy được sự phát triển bền vững cho nền kinh tế của đất nước được dài lâu hơn.

Khi xây dựng hệ thống xử lý bùn thải nhà máy nhiệt điện. Nếu khách hàng cần to buy a sludge press(DECANTER CENTRIFUGE, Screw Press, belt press). Please contact ARK Vietnam for testing and dedicated advice.