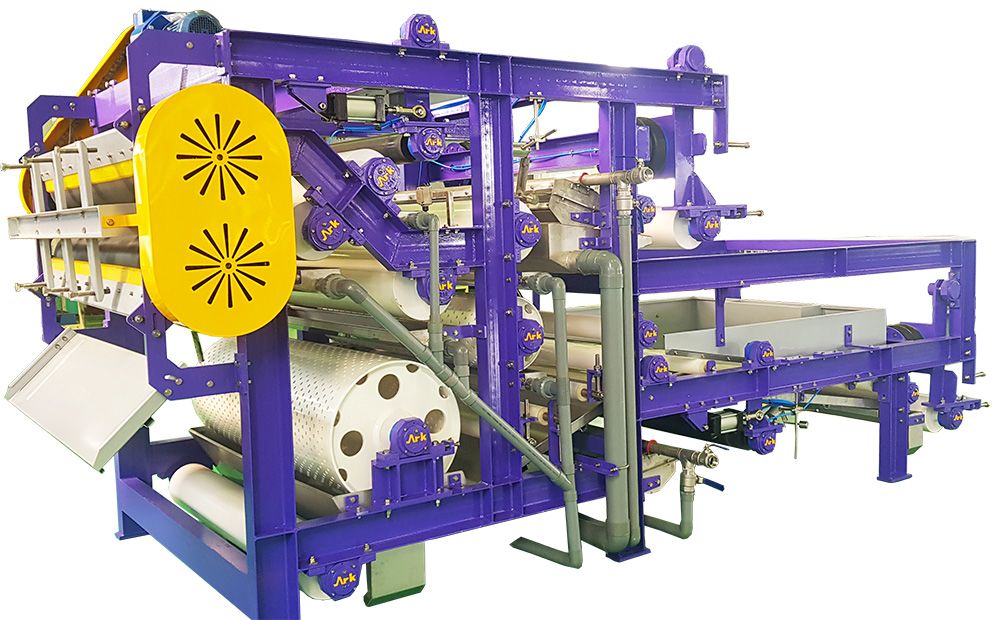

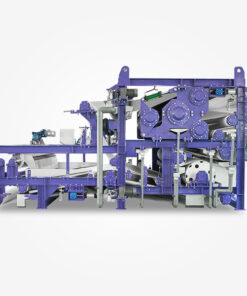

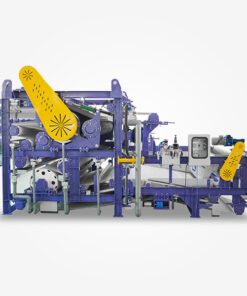

Belt-press is a product that uses the pressure of rollers on conveyor belts to press sludge. Sludge is pressed into thin thickness, has a low moisture content, and quick drying. The main components of the belt press include conveyor belts, rollers, etc.

Overview of ARK Belt-Press

| Production technology | the Republic of Korea |

| Assembled | Manufactured and assembled in Vietnam |

| Sludge | Low humidity, reduced to 65% with high-pressure belt-press |

| Price | Affordable cost |

| Structure | Durable structure, outstanding longevity |

| Operation | Simple, automatic, easy cleaning |

| Repair and maintenance |

Fast, replacement components available in Vietnam |

In recent years, the demand for sludge presses has increased. Companies are increasingly aware of the importance of sustainable development.

Growth in production scale must go hand in hand with environmental protection. Not only serving the Vietnamese domestic market, but ARK is also a reliable and strategic partner of many foreign enterprises.

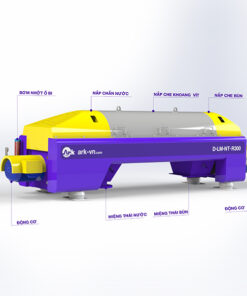

About ARK Decanter Centrifuge

Belt-press (Belt-press dewartering machine) is one of the most important products that ARK Vietnam manufactures and distributes. Belt press of ARK is a new generation of sludge dewatering machines.

We inherit Korean achievement. The machine is manufactured and assembled in Vietnam. The modern production line is directly imported from the land of kimchi. The working principle of belt-press is quite simple. Water shall be pressed out of the sludge under the pressure of the rollers on conveyors.

We have many decades of experience in homeland South Korea, and more than 10 years of presence in the Vietnamese market.

ARK sludge dewatering plays a pivotal role in dozens of large and small wastewater treatment projects. Continuous and durable operation in different environments. Suitable for many types of wastewater with complex physicochemical properties.

Belt-press in particular and other ARK sludge dewatering machines in general, are optimally designed.

It could operates effectively in the treatment of municipal wastewater, feedwater, industrial zones, factories of food processing, slaughtering livestock, poultry, seafood, paper-making, dyeing, tanning, metal plating, mining ...

Principle of operation

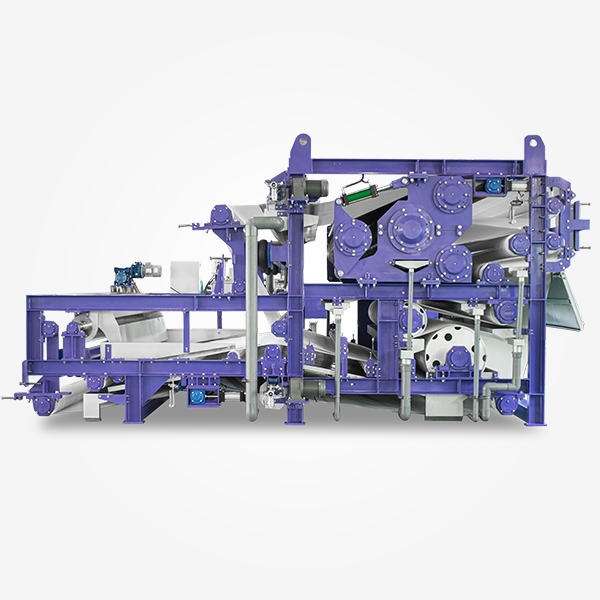

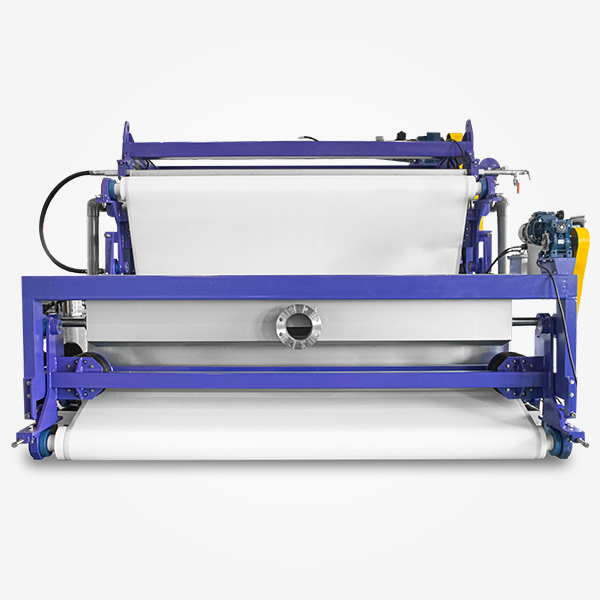

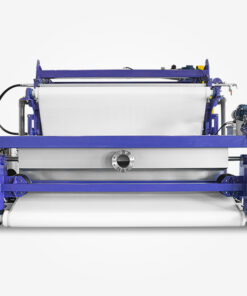

The Belt-press uses the pressure of the rollers on the conveyor to extract the water. Sludge is pressed into thin sheets, low moisture content. The main components of the machine include the conveyor belt, the rollers that press the sludge between the belts.

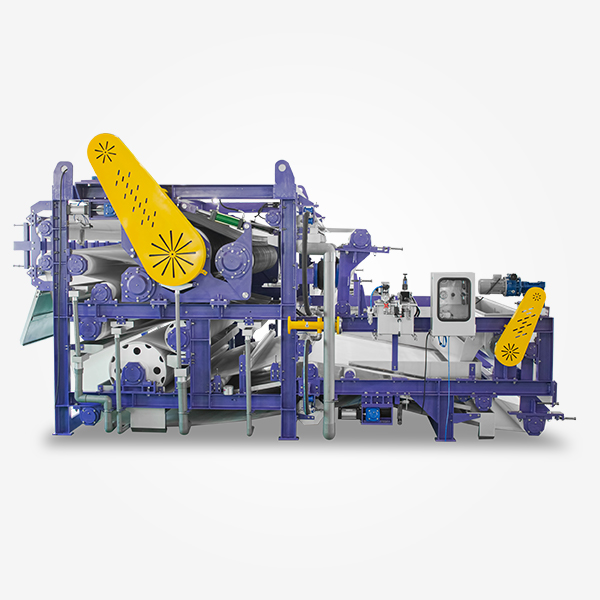

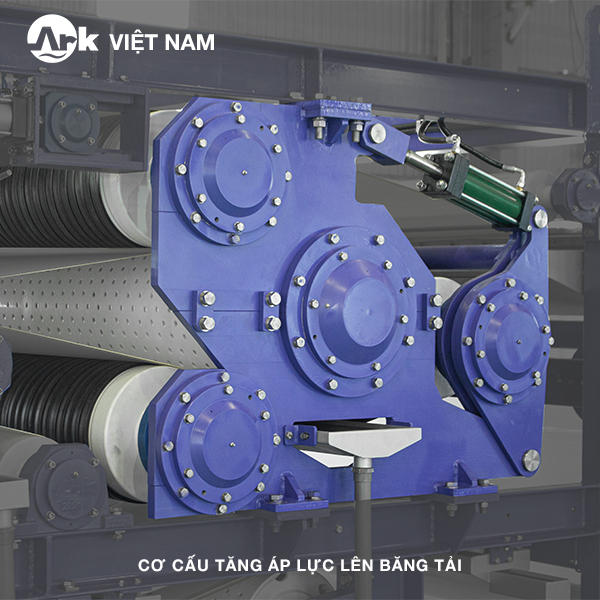

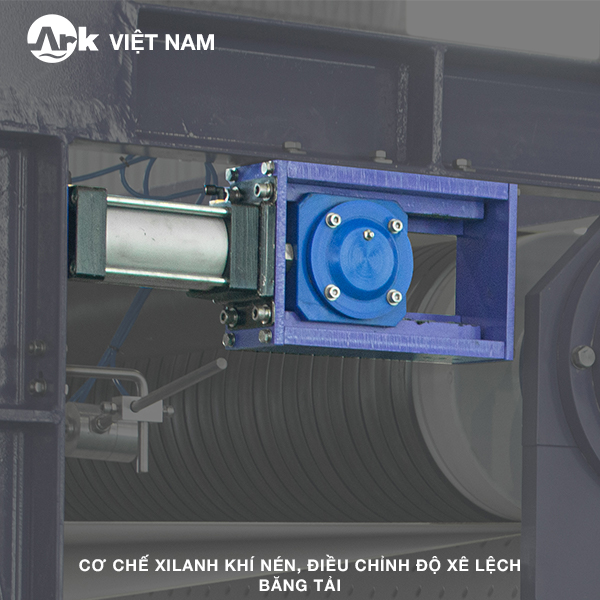

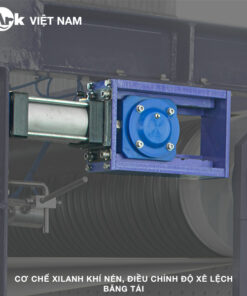

Other parts are alignment devices, gears to help to stretch the conveyors. The goal is to keep them from sagging. The high-pressure belt-press version has a hydraulic booster system that increases the pressure on the conveyor. Therefore, finished pressed sludge would have humidity is 60-65%, it is better to compare with conventional belt-press.

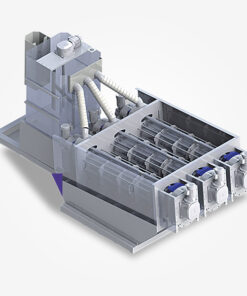

The machine has an open structure. The sludge-polymer reaction tank for sludge precipitation is designed separately. The first stage requires the sludge must be concentrated, flocculated by polymers.

Then exceed water is extracted by gravitation before being fed into the pressing rollers. This initial process increases the sludge concentration from 0.5 - 3% to 5 - 15% by volume. The pressed sludge cake has a moisture content of 60-85%. It depends on the properties of the inlet sludge, the high-pressure version, or the normal version of belt-press.

Advantages of ARK Belt-press

- ARK belt-press is simple to operate and easy to clean. The machine has more sludge pressing rollers than similar products on the market. In addition, the machine also has a large diameter roller, drilled with a drainage hole, which helps to increase the time of sludge pressing and the ability of dewatering.

- The rollers are hot-coated with a special material (exclusive invention of ARK), which increases the resistance to corrosion and abrasion.

- The machine body is mechanized from high-quality steel. This material is resistant to abrasion and many highly corrosive chemicals contained in wastewater. Complying to ISO 9001:2015 standard.

- Machine parts are easy to maintain, repair, and replace. ARK factory locates in Vietnam, thus, minimizing the waiting time of customers.

- The machine works stably, continuously, serving for a long time.

- The pressed sludge can reach 60% humidity by using the high-pressure belt-press version.

Economic benefits when using ARK Belt-press

In certain aspects, ARK-branded belt-press has outstanding advantages. Sludge dewatering technology by conveyor pressure requires frequent belt tension adjustment. The machine is not immune to the odor generated due to its open structure. However, it brings many economic benefits.

The initial investment is affordable. The machine is capable of handling large volumes of wastewater continuously and efficiently.

The machine does not require highly qualified workers because of its simple operation. The humidity of pressed sludge and the capacity can be easily adjusted. At the same time, it allows customers to replace and upgrade machines without affecting the whole wastewater treatment system.

Quality guarantee and after-sales service

The prestige and efficiency of customers are always our top priority. With the help of ARK, customers will be released from the concern of the expensive costs incurred.

In addition to the cost of the belt press (depending on each model/version), customers only have to pay a negligible amount related to operational guidance.

ARK owns a team of professional technicians, dedicated to customer support before and after buying the machine. We maintain strict quality control during design and manufacturing. As well as ensuring quality standards in the wastewater treatment industry.

ARK directly supply, design, manufactures sludge press in Vietnam, and set-up the sludge dewatering machine in your factory. We provide consultant service to help customers to choose the most suitable model. Further is the test run, operation training after set-up the machines. Our hotline is always available.

Auxiliary equipment for ARK Belt-press

The system includes a sludge-polymer reaction tank and a sludge supply pump system.

ARK also provides many types of polymer for sludge treatment at favorable price. Coagulants and flocculants are available in large quantity.

Contact us now for a FREE trial run with enthusiastic and quick advice:

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.

Manh Cuong Construction Development Company Limited –

Excellent product, thoughtful operating instructions, dedicated and reputation after-sales service.

ARK Vietnam –

Thank you for your feedback.