Wood processing wastewater treatment is a method of controlling pollution, especially wastewater, generated during wood processing. Enterprises need to choose the right technology to treat wastewater from wood processing factories to achieve high treatment efficiency.

Why treat wood processing wastewater?

The wood processing industry has become Vietnam's fifth-largest export industry after crude oil, textiles, footwear, and seafood. Vietnam has become the leading wooden furniture exporter in Southeast Asia. The quality of Vietnamese wood products has always been improved, making it competitive with other countries in the region.

Wood brings many benefits to people, wood makes houses, furniture, and essential tools. To meet that demand, many wood processing companies have formed, developed, produced, and processed wooden tools.

Besides the benefits that the industry brings, the wood processing wastewater needs to be treated because: The wood industry also causes problems affecting the environment and human health such as wastewater with high toxic content, hazardous waste, and hazardous waste. Harmful, solid waste, dust, etc.

Causes of pollution from wood processing wastewater

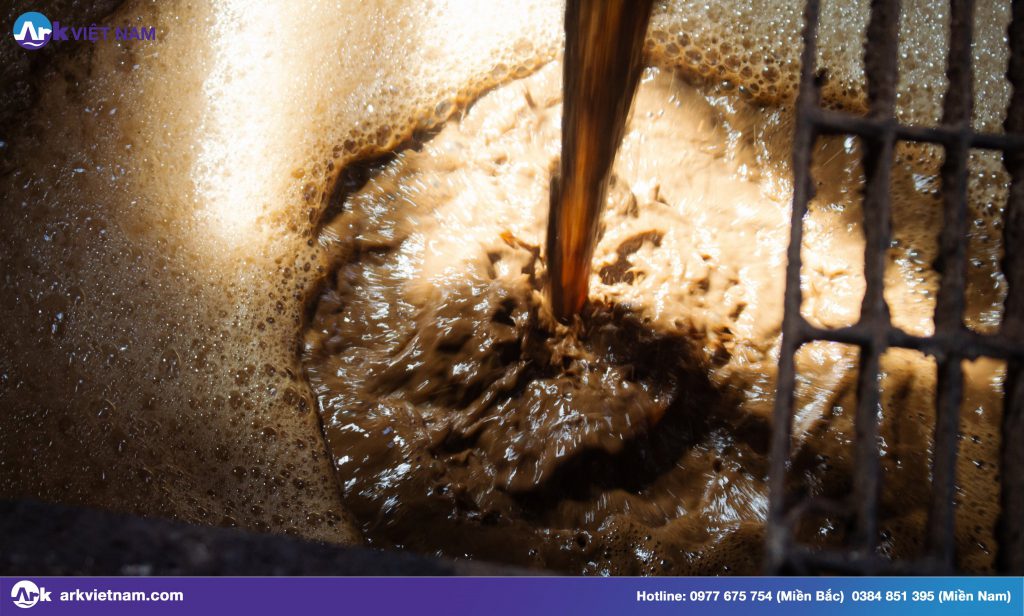

- Boiling wood, impregnating wood, the amount of wastewater is small, but it is toxic because it contains impregnation chemicals and ligin.

- Wastewater generated from the hot bending process

- Wastewater from solvent treatment system, paint dust using leaking steam transmission system, boiler cleaning

- The composition of production wastewater: production wastewater contains substances such as boric, borate, notric, suspended residue, ligin, oil from wood, and paint, ...

Woodworking wastewater contains high concentrations of pollutants, mainly from:

- Arsenic.

- Biochemical oxygen demand (BOD).

- Chemical oxygen demand (COD).

- Copper (Cu).

- Chromium (Cr).

- pH (abnormally high or low).

- Phenol.

- Grease.

- Suspended Solids (TSS).

Thus, wastewater generated during wood processing has a high concentration of pollutants. If not treated, it will cause serious pollution to the environment.

How to treat wood processing wastewater?

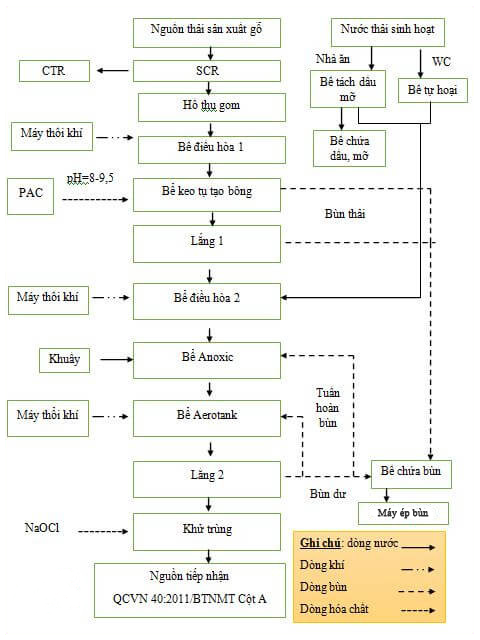

Currently, the most commonly used method of wastewater treatment for wood processing factories is AAO technology. AAO technology is a continuous process of applying many microorganisms: anaerobic, anaerobic, and aerobic to treat waste. Under the effect of the decomposition of organic compounds by microorganisms, pollutants are treated before being discharged into the environment.

Anaerobic process in the treatment process Wood processing workshop wastewater

1 – Hydrolysis: During this stage, under the action of enzymes secreted by bacteria, complexes and insoluble substances are converted into simple substances, this process happens slowly. The rate of decomposition depends on the pH, particle size, and degradability of the substrate.

2 – Acidification: In this stage, fermenting bacteria convert soluble substances into simple substances such as volatile fatty acids, methanol, CO2, H2,….new biomass formation can lower the pH to 4.

3 – Acetication: Acetic bacteria convert the products of the acidification phase into acetate, H2, CO2 and generate new growth.

In the 3 stages of hydrolysis, acidification and acetic, COD almost did not decrease, COD only decreased in the methane phase.

Anoxic process

Wastewater contains compounds N, P. In the Anoxic tank, under anoxic conditions, the anoxic microflora develops to treat N and P through the process of nitrification and phosphoryl.

Aerotank process

The aerobic decomposition process relies on the living activities of aerobic microorganisms, especially aerobic bacteria, which will use dissolved oxygen in the water to decompose organic matter in wastewater, microorganisms. Pseudomonas denitrification, Bacillus, etc. reduce nitrate to N2. General conditions for nitrifying bacteria pH = 5.5 -9 but the best is pH = 7.5, when pH < 7, bacteria grow slowly, dissolved oxygen should be 0.5 mg/l, temperature from 5 - 40°C.

This process occurs rapidly if aeration is present, which will increase the amount of microbial activity by increasing the activated sludge, regulating the nutrient content, and inhibiting the toxins that affect the activity of the sludge, and microorganisms. In addition, the suitable temperature for processing is 20°C – 40°C, and the optimum is 25 – 30°C.

In the Aerotank tank, there are additional contact materials to increase the opportunity for microorganisms to contact wastewater, and an environment for microorganisms to grow and adhere. Dissolved oxygen will be supplied from the air blower through the distribution pipe system. Aerotank's BOD removal efficiency is reduced by about 80 - 85% compared to the input. Therefore, by now, the wastewater has almost been cleaned. Wastewater after leaving the Aerotank aeration tank will overflow through the settling tank 2.

Clarifier

Wastewater continues to be directed to Settling Tank 2 to separate biological sludge. Here, most of the biological sludge (activated sludge) present in the wastewater will be settled at the bottom of the device. Part of the sludge, after settling, will be circulated to the aerobic biological tank. Ensure the amount of sludge is always stable for microorganisms to work. The excess sludge will be processed via sludge dewatering machines.

The clear water after passing through the settling tank will flow through the sterilization tank, the disinfectant (10% NaOCl solution) is simultaneously pumped into the tank to thoroughly treat pathogenic germs such as E.Coli, Coliform, etc. Wastewater after being disinfected meets the standards QCVN 40:2011/BTNMT, column A and discharged to the common sewer. Complete the processing.

Wood processing sewage sludge press machine

Nowadays, businesses use mud presses mainly. To replace the old technology is to use a sludge drying yard in wastewater treatment for wood processing plants. Because of occupying a large area of land for treatment, not to mention waiting time for the sludge to dry.

Epilogue

Wastewater treatment of wood industry is a method necessary. Help businesses protect the environment and avoid legal problems if untreated wastewater is released to pollute the environment.

When building a wood processing wastewater treatment system, if Enterprises need buy sludge dewatering machine woodworking waste(decantation centrifuge , screw press, belt press) please contact ARK Vietnam for advice enthusiastic and attentive.