The chemical metering pump is a specially designed pump line. It specialized in pumping toxic, highly corrosive liquids. In particular, this type of equipment is suitable for pumping a small liquid flow, stable with high pressure.

In this article, ARK Vietnam will clear up the ambiguity about this type of pump, in terms of structure and principle of operation.

Metering pump (dosing pump) is the equipment used to control the flow rate of a liquid. Move exactly one volume of liquid in a specified time.

Pumps are often used to pump highly corrosive chemicals such as acids, bases, toxic substances, viscous, high temperature ... Due to contact with specific chemicals, the pump should be made of corrosion-resistant materials such as PVC, PP, Teflon ...

On the market today, most dosing pumps can be set to parameters, control flow rate manually or automatically depending on actual needs.

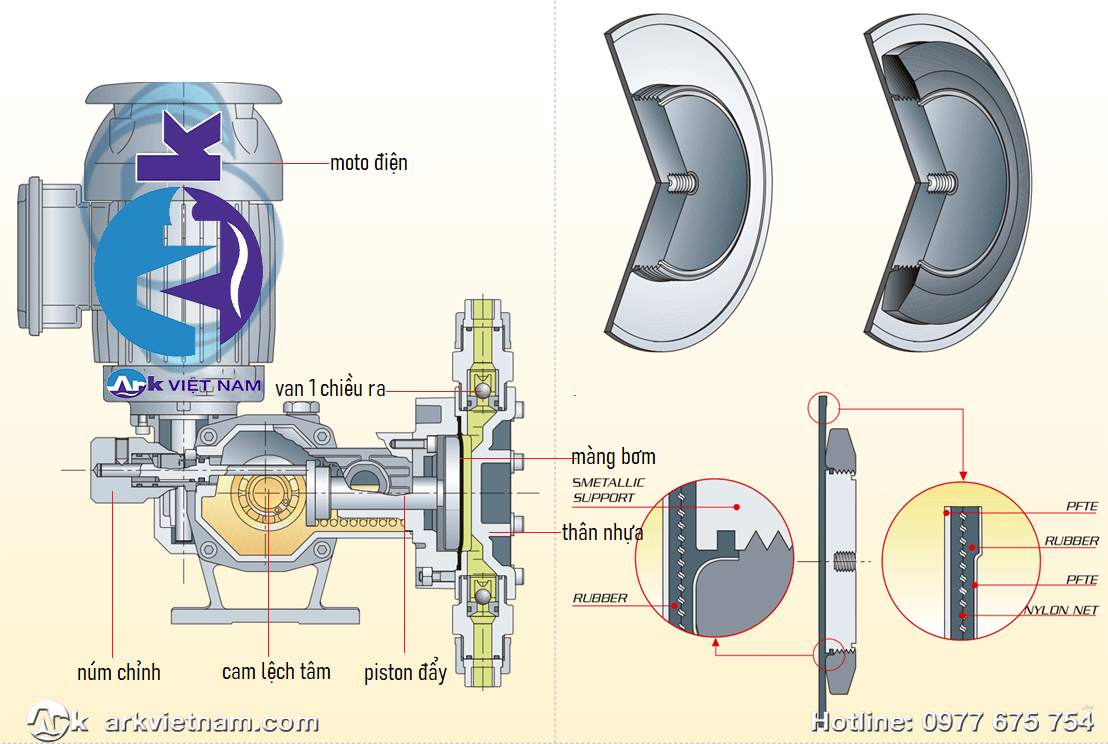

Chemical metering pump Structure

Dosing pumps are distributed with a variety of types and sizes. Each type of pump has a different mechanism and mode of operation. But the structure has many things in common such as:

- Liquid storage compartment: it stored the liquid before being extracted and poured.

- Non-return valve (check valve): usually located at the suction and discharge outlet of the pump to block, or move the solution.

- Conduit: PVC, PE are commonly used. If the pump is used for chemicals with high temperature and high pressure, stainless steel can be used.

- Sprayer: the part that pushes the solution out. The sprayer can be fitted with a nozzle to put chemicals in the middle. This helps limit pipe corrosion.

- Control system: the unit controls and ensures the correct dosing of the solution. It can be automatic or manual.

- Membrane is made of durable, tough, elastic material, suitable for all solutions.

- Pump chamber: depends on the manufacturer, type of pump ... that has different volume, size, and material. Constituent materials have extremely good corrosion resistance such as PVC, PE, rubber, or stainless steel.

- The pump chamber is connected to other parts including the suction, pipeline, discharge, flow sensor (if any).

The principle of operation of the chemical metering pump

The way it works is simple, can be described with 4 processes:

- Self-priming pump: is the first process. Push the liquid into the pump chamber and prime filled the chambers. The chambers can be replenished continuously throughout the pump operation.

- Suction process: When the pump runs, the check valve will open to pump liquid into the pump chamber. When the pump chamber is full, this valve will close.

- Discharge process: Immediately after closing the check valve, the liquid is transferred to the outlet line. The check valve here will open, pushing the liquid out.

- Flow control: The liquid flow will be adjusted according to the need, which can be done manually or automatically depending on the pump type.

Membrane is like a septum in the heart, opens and closes rhythmically

The motor and pushrod will gradually move the membrane to create a vacuum. Thereby creating a suction force that pumps the liquid into the pump chamber. When the pump chamber is filled, the pushrod squeezes, compresses the membrane, and creates pressure to push the liquid out.

What are the benefits of metering pump?

- It is useful industrial equipment, the benefits of the pump are enormous. They are designed to extract specific liquids that require high precision and consistency.

- They dispense high-accuracy, low-flow volumes, in compliance with industry standards.

- Pumps all types of liquids. From dilute to thick solutions, extremely toxic, or highly corrosive.

- Diverse applications, such as medicine, food processing, agriculture, and industry.

- Some kinds of metering pumps (especially diaphragm pumps) can prevent spilled liquids from polluting the workplace and other machinery.

- Metering pumps can run idle for a certain period. However, air pumping is not recommended. This can cause damage to the pump for a long time.

Chemical metering pump classification

There are many famous brands in the world in the production and design of metering pumps. They are very diverse. In general, this kind of pump can be divided into 4 main types:

- Piston metering pump

- Hydraulic metering pump

- Diaphragm metering pump

- Electronic metering pump

In which, ARK Vietnam is manufacturing and distributing Diaphragm metering pump, the leading pump according to Korean technology.

Outstanding advantages of ARK diaphragm metering pump

Diaphragm metering pumps possess many outstanding advantages compared to other conventional pumps, such as:

- Allows adjusting the flow from low to high according to different requirements.

- Sealed structure to prevent liquid leakage, for hygiene and safety.

- Compact size, save set-up space. Easy to move and disassemble.

- Simple structure, low maintenance. Quick repair.

- Durable, wear-resistant materials to ensure compatibility with all types of solutions.

This is a type of trustable pump used to pump liquids containing suspended solids, highly corrosive and toxic. Suitable for systems with strict requirements of leakage and anti-air bubbles.

Application of ARK diaphragm metering pump

The pump is popular in most fields of life. Especially in the water treatment industry, chemical treatment…

In addition, the pump of ARK Vietnam also appears in: oil refineries, petrochemical plants, power stations. In other fields such as:

- Scientific research, laboratory,

- Used to pump paint, glue, ink, sludge ...

- Medicine, pharmaceuticals, food …

- Pump chemicals for industrial production, pulp, anti-limestone cleaner ...

Chemical metering pump market today

In the Vietnamese market today, water pumps in general and metering pumps, in particular, are sold with many different brands and manufacturers with different styles, qualities, and designs.

Diversity is "double-edged sword", It both brings many options for customers and creates difficulties for investors. Among countless products, choosing the right one is difficult.

ARK Vietnam – The best Korean chemical metering pump brand

Therefore, the article would like to recommend ARK Vietnam – dosing pump brand is very popular. We can consult and choose the right product for you, the fastest and most suitable way. Especially for inexperienced customers.

ARK is a manufacturer and distributor of metering pumps, as well as sludge presses from South Korea. Established more than 30 years ago, and more than 10 years of operation and development in Vietnam.

Our products constantly improving quality. Compliance with the strictest quality standards, helps affirm the position of ARK Vietnam in the hearts of customers.

When choosing ARK Vietnam, you will never be disappointed

Phone number: 0977.675.754 (Mr Truc)Website: www.arkvietnam.com

Email: arkvn234@gmail.com

Hanoi Office: 5th floor, N03-T7 Diplomatic Urban Area, Xuan Tao Ward, Bac Tu Liem District, Hanoi.

HCMC Office: 68 - 70 Hoang Dieu Street, Ward 13, District 4, HCM City.