List of technical documents, drawings Decanter Centrifuge ARK Vietnam:

| Model R300 | See now | Download |

| Model R350 | See now | Download |

| Model R400 | See now | Download |

| Model R450 | See now | Download |

| Model R500 | See now | Download |

Free image, technical documents, references, archival catalogue for customers.

List of technical documents, drawings Decanter Centrifuge ARK Vietnam:

| Model R300 | See now | Download |

| Model R350 | See now | Download |

| Model R400 | See now | Download |

| Model R450 | See now | Download |

| Model R500 | See now | Download |

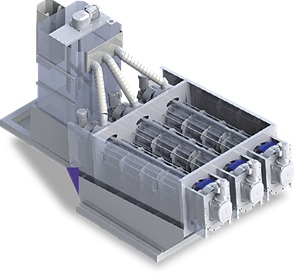

A dewatering machine is used to reduce the amount of moisture in the sludge generated in the sewage treatment plant. Among them, the most frequently adopted dehydrator is definitely a centrifugal dehydrator machine. The centrifugal dewatering machine is a method of separating sludge into solids and moisture using the centrifugal force.

Annotate:

|

|

|

| outer cylinder (Bowl)-1 | a screw conveyor-2 | a gearbox-3 |

The capacity of the centrifugal dewatering machine is primarily proportional to the inner diameter of the outer cylinder, and most of the standards for each company include the inner diameter.

This is a specifications of a centrifugal dewatering machine, such as KOWATS-360D, KOWATS-420D for Company R; 300MTDI, 350MTDI for Company EWHA; DDE3532, DDE4042 for Company H. Or D-LM-NT-R350, and D-LM-NT-R400 for Company A.

Although the treatment capacity is shown according to this specification, each company has different experience values, and each country has different sewage/waste sludge properties, and there is a large difference in treatment capacity for various reasons such as reference sludge concentration and organic content. For this reason, it is difficult to write down the treatment capacity on a certain basis.

The excess sludge concentration of 4% or more is difficult to react by mixing polymer and sludge. However, raw sludge, mixed sludge (excess + raw sludge), and sludge with high inorganic content are estimated that it is possible to treat. But it is preferable to check the degree of reaction with polymer, before treatment.

There are various type of sludge depending on concentration, pH, fiber content, inorganic content, and other ionization degree, and has very different throughput and water content depending on these properties, and thus consultation with an expert is needed.

List of technical documents, catalogs, AutoCAD drawings of screw press ARK Vietnam:

| User Manual Book | See now | Download |

AutoCAD drawings of type KS-ST:

| Model S-ST201 | See now | Download |

| Model S-ST202 | See now | Download |

| Model S-ST203 | See now | Download |

| Model S-ST204 | See now | Download |

AutoCAD drawings of type KS-RT:

| Model S-RT201 | See now | Download |

| Model S-RT202 | See now | Download |

| Model S-RT203 | See now | Download |

| Model S-RT204 | See now | Download |

| Model S-RT401 | See now | Download |

| Model S-RT402 | See now | Download |

| Model S-RT403 | See now | Download |

| Model S-RT404 | See now | Download |

|

|

| RT Type | ST Type |

The dehydrator multi-disk screw press was developed in Japan around 1990 and is popular in South Korea and China, and is gradually spreading to Europe, The dehydrator multi-disk screw can divide two types according to the driving method, but the basic principle is that the flow plate moves with respect to the fixing plate, the dewatering water is emitted through the gap between the fixing plate-1 and the flow plate-2, and the sludge is compressed with a screw rotating inside the muti-disk cylinder.

Annotate:

The dehydrator capacity is primarily proportional to the screw diameter, and the specifications for each company is often indicated by diameter.

Most of the specifications do not match the screw diameter, it is necessary to check which part of the diameter the specification indicates. Included is the number of screws integrated in the machine. Example:

Although the treatment capacity is shown according to the specifications, each company has different experience values, and each country has different sewage/waste sludge properties, and there is a large difference in treatment capacity for various reasons such as reference sludge concentration and organic content.

For this reason, it is difficult to write down the treatment capacity on a certain standard. The name of the model already shows its structural characteristics.

Generally, if the concentration is over 0.6%, the treatment capacity of the multi-disk dehydrator is affected by the sludge solid content rather than the treatment volume, and if the concentration is below 0.6%, the treatment volume is affected.

However, when the screw diameter is 400 mm or more, the treatment of dehydration is not increased proportionally according to Screw diameter and the moisture content may be increased highly.

List of technical documents of belt presses:

| Model W650 | See now | Download |

| Model W1000 | See now | Download |

| Model W1500 | See now | Download |

| Model W2000 | See now | Download |

| Model W2500 | See now | Download |

| Model W3000 | See now | Download |

|

|

| Standard type | High-pressure type |

The Belt press dehydrator is the earliest developed dehydrator and is the first model introduced in South Korean wastewater treatment plants, and has been the most popular in the past. However, when washing the belt, a large amount use of water and difficult to collect odors in a sealed structure, so it is significantly less used in South Korea than before.

The belt press dehydrator consisted of a pair of filter cloths and a plurality of roller systems. The belt press can be divided into four dehydration zones as below. The sludge introduced into the gravity dehydration unit is sequentially separated into filtrate and cake.

Annotate:

If the belt press dehydrator is largely classified, it can be classified into a general dehydrator with 6-8 stages of general rollers.

The high-pressure belt press that compresses at high pressure by inserting a separate driving device of the high pressure into the general dehydrator. In addition, belt presses such as paper wastewater can be classified into special belt presses designed to suit sludge with high use efficiency.

|

|

|

|

| Air-pressure support mechanism maintains the belt tensity | Sensors detect the deviation of the belt | Mechanism adjust the belt in case it deviates | Hydraulic mechanism to increase the pressure on the belt |

Each type of ARK's belt press is divided according to the width of the filter cloth. With widely used versions such as:

The initial sludge with low sludge concentration needs to be concentrated by 2-3% or more, to work efficiently.